Introduced: 2024

ScaleTrains.com's "Rivet Counter" SD40-2 models are available either DCC-Ready or with a factory-installed ESU sound decoder. Each model has its own unique paint and detailing package (based on the prototype in question). These are amazing looking models that are at least capable of running quite well. However, SD40-2's from the first production run do have one serious design flaw that owners will likely need to address before they can actually run one (more on that shortly).

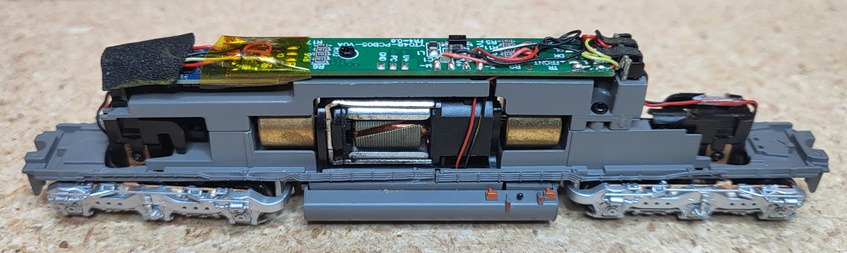

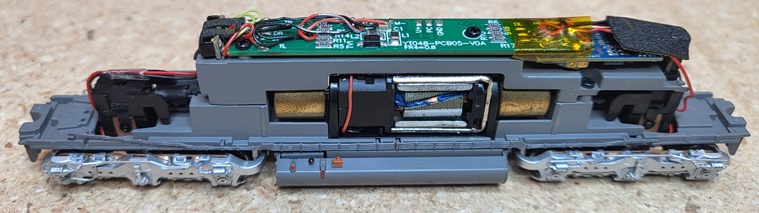

Internally, these models are quite similar to STC's previous diesel releases (GEVo, C39-8, C44-9W). The chassis consists of a metal base with a metal bracket screwed to the top (holding the motor and drivetrain in place). The motor is an open-sided 5-poler with skew-winding. Each motorshaft is equipped with a flywheel (although they are somewhat ineffective, as these locos start and stop on a dime without the aid of a decoder). Plastic driveshafts seat inside of the flywheels and connect to notched cups on the truck towers. Short metal shafts connect the cups to the brass worm gears mounted inside the truck towers.

The main PC board is screwed to the top bracket and receives current from the trucks by way of four wires. Separately wired boards fore and aft of the main PC board provide bright white LED lighting for the forward numberboards, headlight, rear numberboards and backup light. The headlight and backup light are directional whereas the numberboard lighting is constant (always on). Additional wires run from the main PC board to the motor and (for DCC-Sound models) to a speaker mounted inside the fuel tank. The decoder interface on the DCC-Ready main board is "E24".

All six axles are geared and all gearing (apart from the worms) is plastic. The wheels are blackened and low-profile (no problems on Atlas Code-55 track). There are no traction tires. STC's MTL-style automatic couplers are mounted to the chassis. Note that I've replaced the stock couplers with MTL's in the picture below, this because the stock couplers fell apart on me when I took the shell off and then refused to stay together when I tried to put them back in (hugely annoying since coupler removal is required if you want to take the shell off).

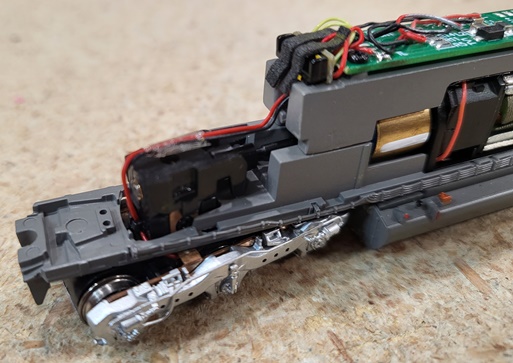

The plastic fuel tank is screwed to the bottom of the chassis. Holes in the fuel tank are provided for the speaker. For the DCC Sound models, the speaker is seated inside of a pocket in the chassis. And ignore the mangled fuel tank for now, there was a problem with the first production run that I'll get to shortly.

All 12 wheels provide pickup by way of axle-end wipers (the axle ends seat inside of holes in said wipers). Wires soldered to the axle wipers transfer current to the main PC board. As pictured, the trucks are a rather complex assembly and removing them would likely be a rather daunting proposition. An extension on the top of the plastic truck tower assembly holds the trucks inside the chassis, and so I guess you would basically have to completely disassemble the truck towers and disconnect the driveshafts in order to get the trucks off.

Shell detailing is beyond amazing, including see-through fans and actual sand lines (AFAIK, a new feature for N scale diesels). That said, I must register my displeasure with the flimsy handrails and the fact that the stanchions pop loose if you so much as look at them wrong. Very annoying.

These are very nice runners - smooth, whisper quiet, excellent slow-speed creep and a realistic top-end speed. Mine ran well right out of the box, so pre-emptive wheels cleaning doesn't appear to be required. Mine can creep through insulated frog turnouts at very slow speeds, so pickup is flawless. Pulling power is decent (if unspectacular), with mine able to handle about 35 assorted 40' freight cars through curves on level track (any more than that and the wheels are slipping). I didn't have any problems with the wheels derailing (even on 9.75" radius curves). The sound isn't bad, although perhaps just a bit thin and tinny sounding to my ear (which is pretty much my opinion of most N scale sound installations these days).

One minor annoyance I have with the ESU decoder is the whole protracted "start up" sequence the locomotive goes through when moving from a dead stop (basically the locomotive sits there making various noises for 4-5 seconds before it starts moving). All very prototypical I'm sure, but not something I really want to have to deal with (particularly when MU'ing an STC loco with some other brand of loco that just wants to go). Changing CV124 from 4 to 16 eliminates this behavior. Also, the default behavior is for sound to be off when you first put the locomotive on the rails (with F8 then turning it on). If you want the reverse of that (sound comes on when you put the loco on the rails and turns off with F8), set CV31=16, CV32=2, and CV419=32.

For the DCC-equipped models, some CV tweaking may be necessary in order to achieve optimum performance. Out of the box, mine exhibited a very slight stutter at speed step 1 (IE, it wouldn't maintain a consistant speed). So, I performed a CV54 "BEMF auto tune" (set CV54 to 0 and then hit F1), which smoothed things right out. Another option would be to lower the value of CV56 (default setting is 255) to reduce the amount of BEMF influence over the speed. Yet another option to adjust BEMF would be to increase the value of CV52 from its default setting of 15. Between those three CVs, it should be possible to address any BEMF-related glitches that might arise.

OK, so let's talk about that fuel tank. Due to problems with the chassis paint and the fuel tank screws, the fuel tanks wound up sitting mere molecules away from the rails on the first production run of these models. I mean honestly, you'd be hard pressed to slide a piece of paper underneath that tank -

But this is prototypical, right? Uh no, sorry Charlie, not even close!

Clearly this is a huge problem since that fuel tank is going to bottom out on any sort of track unevenness. IE, unless your layout is 100% flat and your track is laid 100% flawlessly (which maybe applies to three people in the whole world), this is not going to be a runnable model as delivered. Making matters worse, many of these models were poorly assembled and come with the fuel tank already touching the rails! Vis -

Now, to their credit, STC owned up to this problem fairly early on and issued a set of Repair Instructions for these models. But know this - the tiny little screws that hold the fuel tank in place are screwed in using some sort of thread locker and are absolutely impossible to remove without damaging the heads (at least for me), thus making most of STC's repair suggestions impossible (again, at least for me). What I wound up doing was grinding the bottom of the fuel tank to provide some clearance (yikes). The good news is that the problem was fully addressed starting with the second production run. First off, the screws were shortened such that they no longer bottom out before the tank is on all the way. Also, there is less paint on the bottom of the chassis, so it no longer puckers at the screw points. The end result is a noticeable amount of daylight between the bottom of the fuel tank and the rails, so all should be good going forward. Just avoid those stinkers from the first production run!

Prototype -

In January 1972, Electro-Motive Division (EMD) of General Motors would build the first production models of a locomotive design that would prove to be legendary: the SD40-2. The flagship of the "Dash-2" series of 1972, the SD40-2 would build upon the lessons learned from its predecessor, the SD40. While the sixteen-cylinder 645E3 turbocharged prime mover remained the same from its SD40 cousin, the SD40-2 boasted a modular, solid-state electrical system, which featured removable "cards" in place of troublesome relays in its high-voltage cabinet, greatly simplifying electrical troubleshooting and repairs.

Externally, the biggest change was the use of the new HT-C three-axle truck in place of the Flexi-coil C of the SD40. The new truck promised greater adhesion, and was longer than the Flexi-coil C, necessitating an increase of the length of the SD40-2s frame to an overall length of 68', 10" over the couplers. This also had the effect of giving the SD40-2 its characteristic long walkway "porches" at each end. Other small external improvements, such as longer battery box compartments, rear overhang on the cab roof, and drip rail over the front cab door, added to the list of external differences between it and the SD40.

Domestic production of the SD40-2 continued until July 1984 making it one of EMD's most popular locomotives of all time. Many remain in service today, both with original owners as well as secondhand operators. Within the last five years, Norfolk Southern and CSX have rebuilt hundreds of SD40-2s to extend their operating life. This will ensure this venerable locomotive's presence on U.S. rails for decades to come.

The unique EMD SD40T-2 "Tunnel Motor" was the backbone of the Southern Pacific and Rio Grande fleets during the 1970s and 1980s. They were distinguished by the see-through radiator grilles at the rear of the locomotive.

Features -

- All-new model

- Fully-assembled

- Multiple road numbers

- Body mounted knuckle couplers; Micro-Trains compatible

- Coupler box accepts Micro-Trains 1015/1016 couplers without modification

- Factory-applied wire grab irons, windshield wipers, trainline hoses with silver gladhands, and more

- Numerous prototype-specific details

- Motor with 5-pole skew wound armature

- Dual flywheels

- All-wheel drive

- All-wheel electrical pick-up

- Directional LED headlights

- Printing and lettering legible even under magnification

- Operates on Code 55 and 80 rail

- Packaging safely stores model

- 9 3/4" minimum radius, 11" recommended radius

- DCC ready with E24 connector

DCC Features -

- ESU LokSound 5 DCC & Sound decoder with "Full Throttle"

- Single cube-type speaker

- EMD 16 Cylinder 645E3 prime mover

- Operates on both DC and DCC layouts

Shell Removal -

To remove the shell, unscrew and remove the couplers. Once those are out of the way the shell will readily lift up and off.

Grade: A (although "D" for the first production run)