Introduced: 2024

These RTL Turboliner sets are available either DCC-Ready or with factory-installed ESU sound decoders. They all come in five-car sets (two power cars, two coaches and a cafe car). Add-on coach and cafe cars are also available.

All cars come with interior lighting and fully detailed interiors -

The shells (and all of their assorted detail parts) are plastic -

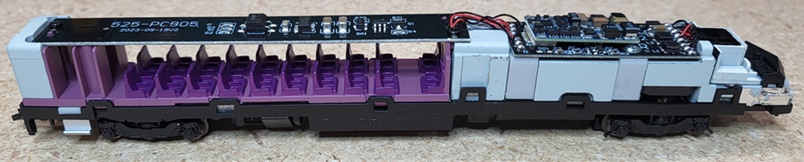

Both of the power units are motorized. For the sound-equipped versions, each powered unit comes with its own decoder and speaker (the speaker is wired up inside the fuel tank and the decoder plugs into a Next18 DCC interface on the main PC board). The chassis is a single piece of plastic, to which the seating section and drivetrain sub-chassis clip.

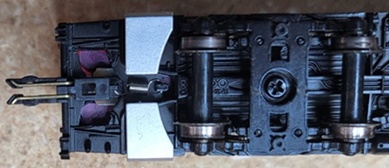

The drivetrain seats inside of a split-frame chunk of metal clipped to the front of the chassis. This sub-chassis is held together by two plastic clips that straddle the tops of the halves. The PC board screws to the top of the sub-chassis (through one of the clips). And good luck getting those screws unscrewed - I couldn't even budge them! An LED board wired to the front of the main board provides light for the strobe lights, class lights and emergency light. An additional LED board underneath the front of the sub-chassis provides light for the headlight and the red marker (reverse) lights. Wires off the back of the board transfer current to the motor and the speaker.

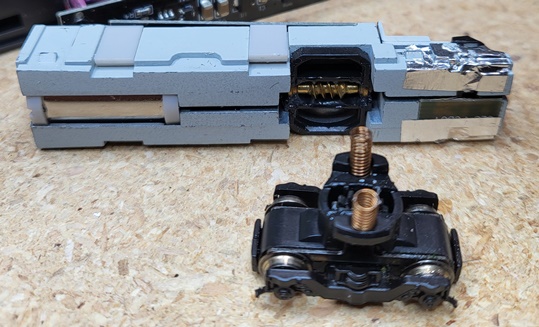

The motor is a round can, which I presume makes it coreless and 5-pole / skew-wound. The single motorshaft is equipped with a brass flywheel. A short plastic driveshaft connects the flywheel to the wormshaft. The brass worm sits inside of a plastic mount wedged underneath the sub-chassis. Bushings on either end of the wormshaft secure it to the mount. All four wheels on the forward truck provide pickup (via axle-top wipers). There are no traction tires. Metal springs mouted on top of the wipers transfer current to the sub-chassis (current then reaches the PC board by way of those aforementioned unmoveable screws). The forward truck pops off and goes back on with minimal effort (just be careful not to lose the springs).

Both axles on the forward truck are geared and all gearing is plastic. Wheels are blackened and low-profile (no problems on Atlas Code-55 rails). Handy-dandy arrows on the powered trucks indicate which end is the front. The PC boards inside the three coaches and the coach shells have similar arrows.

The rear truck on the power units picks up current from all four wheels (as pictured below, said truck is not motorized). The tips of the axle wipers transfer current to contact strips inside the chassis. Metal springs inside the seating detail then transfer current to the lightboard. Wires from the front of the lightboard then transfer the current to the main PC board.

All of the wheels on the three coaches provide pickup using a scheme similar to the rear truck on the power cars.

Current is shared between all the cars courtesy of stiff wires embedded inside of the specialized plastic couplers. Said couplers are plastic and a bit flimsy/bendy.

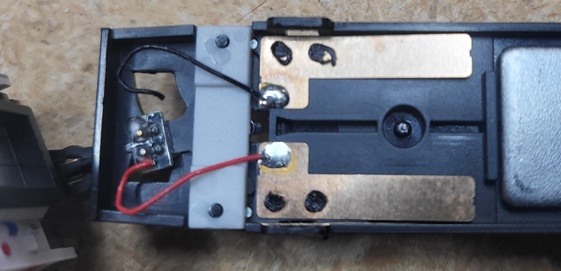

Current flows between the couplers and all the various PC boards by way of insulated wires (along with the aforementioned springs). This is a very problematic scheme since those couplers are constantly pivoting back and forth through curves and stressing the wires. As pictured below, one of the solder joints on one of my coaches failed after just a few hours of running -

These are terrific looking models with fine paint and detailing. And they definitely run every bit as good as they look - smooth, quiet and just flat out perfect. That said, I do find that getting all the cars situated on the rails and hooked up to be a very tedious procedure. The axles barely seat inside of their wipers and tend to pop loose with just the slightest amount of downward pressure on the car. Also, the couplers are (as mentioned above) pretty flimsy, and getting them to lock together is very hit and miss. When pushing two cars together you'll sometimes you'll hear the "click" that means the cars have coupled, but in actuality all the couplers did was bend each other out of the way. Very annoying. Also, I find the sound of the prototype to be grating in the extreme and would never run this set with the sound turned on (of course, that's just me). And lastly, leave us not forget the potential truck wire issues. So, a very nice train for the most part, but ultimately there are just enough warts to keep it out of the "A" category here.

Prototype -

In the early days of Amtrak, efforts were made to improve passenger services along key corridors. Following the success of the French-built RTG Turboliners in the mid-1970s in the Midwest, Amtrak turned to Rohr Industries in California to build modernized Turboliners for use along the Empire Corridor. Entering service starting in September 1976, these new RTL Turboliners quickly proved their value, bringing passengers back to the rails. Equipped with third-rail shoes, they operated on electric power through New York's Grand Central Terminal (and later Penn Station), switching to gas-turbine power once out of New York City. Painted in Amtrak's stunning red, white and blue Phase III paint scheme, they operated on most Empire Corridor services, as well as regular appearances on the Adirondack to and from Montreal in the early years. Occasional equipment needs even put the Turbos on other rare adventures outside their normal call of duty, including the Niagara Rainbow to Detroit via Southwestern Ontario, and the Maple Leaf to Toronto via Niagara Falls.

After nearly 20 years of service under their belts, Amtrak selected one RTL set in 1994 to be rebuilt into what would be called the RTL-II, incorporating several improvements including new turbines, a remodelled interior, a striking new demonstrator paint scheme, in addition to extending the lifespan of the set for several more years. While this set continued in service until 2003, no other RTL-II sets were ever commissioned. Further redevelopments and improvements of the fleet into the RTL-IIIs was never fully realized, and all were retired from active service in 2004. Conventional equipment has since been utilized on the Empire Corridor services in place of the once mighty Turboliners.

Features -

- Accurately designed using original blueprints and field measurements

- Tinted windows, interior details and flicker-free interior lighting

- Separate factory installed grab irons

- Highly-detailed trucks including third-rail shoes

- Working headlights, marker lights and cab-mounted strobe lights

- Both Power Cars come with smooth, reliable drive systems for optimal performance

- DCC models feature ESU sound decoders in each power car with accurate sounds sourced and remastered from original videos

- All wheel electrical pickup

Shell Removal -

Each shell has four plastic claws that slot into the chassis. Pry the sides of the shell away from the chassis to free up the claws and the shell should lift right off. The power car shells have two additional claws that slot into a blue shroud underneath the front of the chassis. First, unscrew and remove the coupler box cover, then gently pry up on the shroud to free up these extra claws.

Grade: B