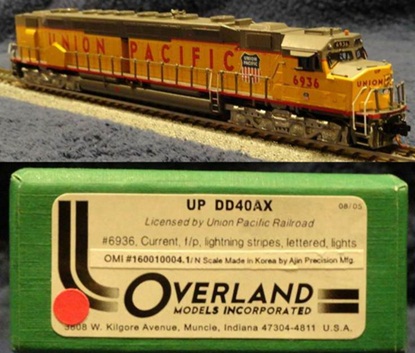

Introduced: 1983 (second run in 2005)

This was OMI's first Ajin-made brass import. And for whatever reason, it would be over a decade before they hooked up again (their 1995 GE AMD Genesis collaboration). As noted above, there have been two different releases of this model (and with the two having significant differences). First-run models are easily identified by their OMI catalog number on the box (OMI-2800).

According to Overland, "The 1983 version was imported with rather crude details compared to today's expectations (thick handrails, thick stanchions, etc). Further, the original unit was imported unpainted and had a very rough drive mechanism. The new version was factory painted in Korea with multiple detail and paint variations. The newer unit has better performance and lighting as well".

Oddly enough, if I didn't know any better I'd say these first-run models were actually cobbled together from old Samhongsa parts. The trucks and truck towers in particular being very reminescent of that firm's design -

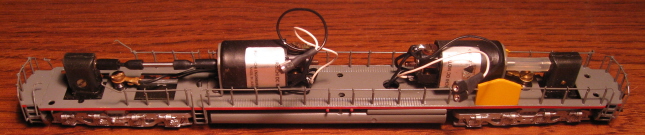

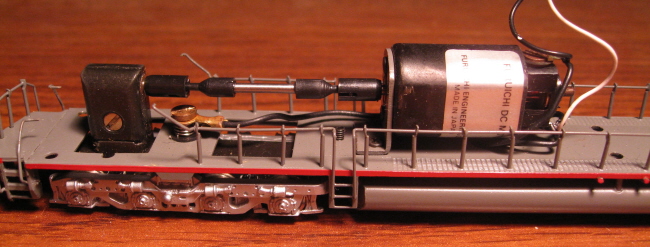

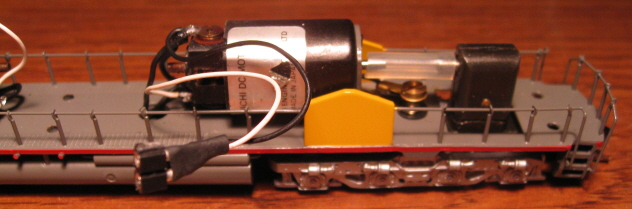

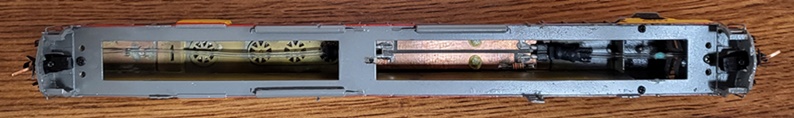

The chassis is all metal and quite hefty. Each truck is driven by its own dedicated can motor (made in Japan by Furuichi). The electrical pickup scheme system is a bit disappointing, what with each truck only picking up a single rail (four wheels per truck providing pickup). Current is ferried around via miles of wiring. All wheels are geared and all gearing is metal. There are no traction tires. Directional lights are mounted inside either end of the shell. Lengthy wires from the motors conduct current to each of the lights. Fortunately, said wiring includes plug/socket connectors, allowing the shell and chassis to be completely separated. Wheel flanges are reasonably sized, so no problems on Code-55 rails.

As delivered, the motor driveshafts are connected to the wormshafts by way of various plastic U-joint connectors. However, due to issues with the rear driveshaft assembly, OMI opted to include a short piece of flexible (Neoprene) tubing as a "do it yourself" replacement for the stock U-joints. Said replacement connector is pictured in the above photos.

I'm not sure if these came with couplers or not. Mine only came with one, and I don't know if that means it started with none and one was added, or if it started with two and one was removed. In any case, Micro-Trains friendly coupler pockets are provided on either end.

Despite Overland's handwringing, I think these first-run DD40's are terrific looking models with gorgeous paint and detailing (including window glass and painted number boards). Like the prototype, you can see right through the middle of thing (which probably explains the whole dual/separated motor design). Unfortunately, performance is pretty mediocre. First off, they're distractingly loud. I don't know if that's due to the motors, the driveshafts or all that metal gearing (or all of the above). But whatever the case, it's annoying. Secondly, pickup is generally kind of iffy (not surprising, given the "one rail per truck" design). And lastly, they're useless on curves sharper than 19" radius (where they will instantly derail). So, no, not horrible. But then again, not anything I'd want to try operating on a model railroad.

For the second run, the mechanism was completely redesigned -

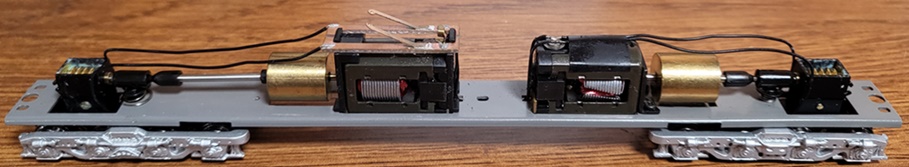

The motors are now open-sided, skew-wound 3-polers and equipped with large flywheels. The Samhongsa-esque truck towers have been replaced with more traditional worm-gear boxes, the driveshafts are completely redesigned, and some of the metal truck gearing has been changed over to plastic. Lastly, the pickup scheme was changed such that each truck now picks up both rails (four wheels on each truck collect current via wheelback wipers).

Given the sticky-uppy metal contacts on the chassis, there is no longer a need for annoying lighting wires -

Performance is improved over the first version, running quite a bit smoother and quieter. It's still a bit growly/grindy sounding (particularly at the high end of the throttle), but quite decent at normal operating speeds (once lubricated and broken in). I think that the dual motor setup is always going to result in some wheel noise if the two motors are not perfectly speed matched. I'm not sure what the minimum operating radius is for curves, but they definitely can't handle 11". I suspect that 19" is (once again) where they will be happiest. On the plus side, pulling power is excellent (50+ cars).

2005 version -

Shell Removal -

To remove the shell on the first version, simply unscrew the four screws by the coupler pockets (two on each end). The handrails around the cab will then need to be freed up in order to totally remove the shell. Also, the aforementioned lighting wires will need to be disconnected.

The second version has 3 screws on each end of the chassis; remove the outer 2 screws on each end and leave the inner screws alone. Next remove the 2 screws that hold the fuel tank to the chassis. This will reveal the final screw that holds the shell to the chassis in the middle. The shell and handrail/sidesill assembly all come off as a single unit, so there is no need to disconnect any handrails on this version.

Grades: C (for the 1983 release) and B (for the 2005 release)