A2 -

A3 -

A4 -

A5 -

A2 -

A3 -

A4 -

A5 -

Introduced: 1984

These Northern Pacific steamers all came out at the same time, and as such I'm going to go ahead and assume that they all share the same basic internals and cover them all here based on the one A2 I've actually purchased and tested. These 4-8-4's were Samhongsa's first ever N scale steam locomotives. And although terrific lookers with fine paint and detailing, they do have their issues in the performance department (but more on that in a moment).

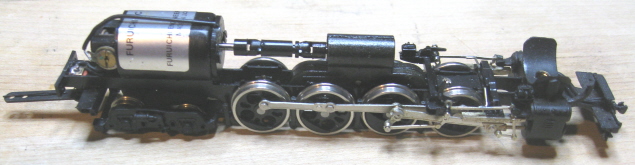

The engine chassis is all metal and fairly minimalistic (with most of the model's heft provided by the brass shell). The motor is a closed-sided 3-poler (made in Japan by Furuichi). Right-rail pickup comes from the four right-side drivers (there are no traction tires). Left-rail pickup comes from the six left-side tender wheels (with current transferred from the tender to the motor via a stiff wire on the tender drawbar). The pilot and trailing trucks are electrically neutral. A multi-piece plastic driveshaft turns a worm inside a spring-mounted worm gear box. Only the center pairs of drivers are geared (with the outer pairs being turned solely by the cranks). The gears aren't actually visible, so I don't know if they're plastic or metal (and unless you want to completely dismantle the model, forget about ever lubricating them). Wheels are low-profile, so no problems on Code-55 rails. There is no lighting. A static (non-operational) knuckle coupler comes mounted to the pilot. There is no coupler on the tender (although a coupler mounting screw does come preinstalled in the coupler pocket, so adding a Micro-Trains coupler looks to be a simple operation).

Performance-wise, these models are at least capable of running extremely well. Give them a nice stretch of straight track and they will glide along just as smoothly and quietly as can be. Slow speed creep is excellent. The top-end speed is a bit excessive, but not crazily so (I've certainly seen worse). No problems derailing on curves as sharp as 11"-radius. Pulling power is exceptional.

Unfortunately, the "stiff wire" current conductivity scheme employed on the drawbar is a major weak point. It is very difficult to get a reliable connection - basically boiling down to the luck of the draw. Sometimes things hook up great and your steamer will run around in circles for hours with nary a hiccup. And other times, the connection winds up being a bit more iffy - with the end result being a lot of stuttering and stalling (particularly through curves, where you have the drawbar pivoting on the tender post). Now, if one were to replace (or augment) the drawbar wire with an actual insulated mini-wire (running from the tender to the motor), you'd have an exceptionally fine running and 100% reliable steamer. But as delivered? Not so great.

To remove the engine shell, first remove the screw that holds the pilot truck in place. Next, remove the pilot truck spindle itself (which also functions as a screw). Lastly, remove the two small screws on the back of the cab. The shell should lift up and off at that point (although it's a pretty tight fit - so, make sure you're lifting straight up).

Grade: C