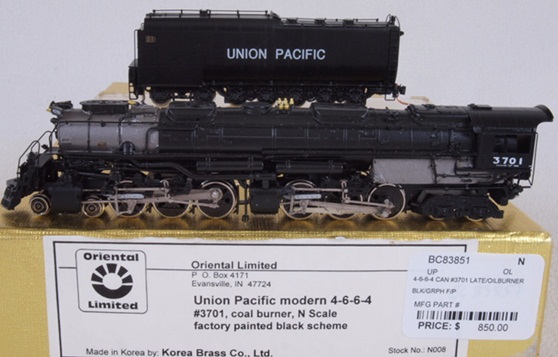

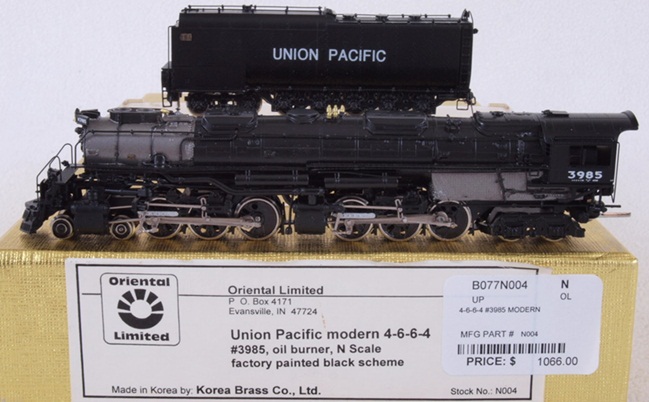

Introduced: 2001

These models were released in three different variants - coal/freight, oil/freight and oil/passenger. And although the one I wound up purchasing runs quite well, I'm told by others that most of these had a lot of "as delivered" problems (poorly applied details, seized mechanisms, etc). Consequently, Oriental Ltd issued a full-blown recall for the problematic units shortly after their initial release.

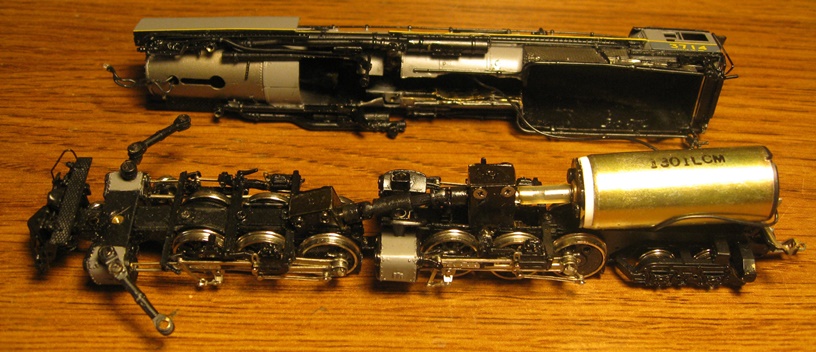

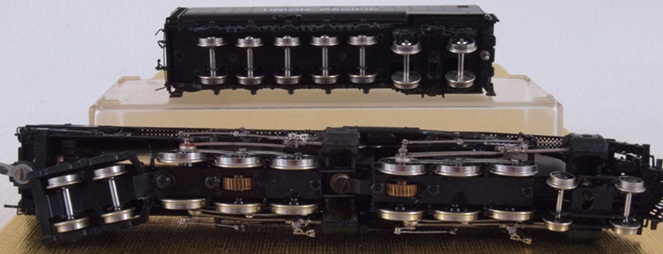

Internally, these models are fairly unique (at least as compared Samhongsa's brass articulateds) -

The motor is mounted firmly to the chassis (IE, no torque arm). And although I'm told that it's a coreless Canon LN14, mine is labeled "1301LCM" (for whatever that's worth). The motor is connected to the rear gearbox by a piece of flexible plastic tubing, whereas the two gearboxes are connected by a multi-piece (telescoping) plastic driveshaft. The drivers pick up right-rail current and the tender wheels pick up left-rail current (with current flowing from the tender to the locomotive by way of a single stiff wire on the tender drawbar). The pilot and trailing trucks are electrically neutral. The locomotive pilot has no provision for a coupler, although it does have a directional headlight (mounted inside of a metal housing, and with the wires then running up inside the boiler).

The backup light detailing on the tender is non-functional (IE, no bulb). A coupler screw hole is provided in the rear/base of the tender. It's a tight fit (vis'a'vis the cut lever detail), but a Micro-Trains 1025 should fit in there (bending the cut lever bar downwards, as per the prototype).

The front engine is free to pivot, whereas the rear engine is not (as per the prototype). The #3 drivers on the front engine are geared, as are the #2 drivers on the rear engine (and with all the rest of the drivers being turned by the cranks). The non-geared drivers are mounted on coiled suspension springs, whereas the geared drivers are not (IE, the geared drivers are not free to move up and down). The two engines are joined together by a metal bar (with screws on either end). There are no traction tires. Wheels are low-profile, so no problems on Code-55 rails. The minimum turning radius is right around 19" (any sharper than that and the wheels start derailing all over the place).

Overall performance on the one I have is, for the most part, quite excellent. Throttle response is smooth, it runs very quietly, and pulling power is strong (30+ freight cars without difficulty). The model exhibits no shimmying, shaking, wobbling or any other "bad running gear / out of quarter" problems. The headlight doesn't flicker as it runs along, so the old school "stiff wire on the drawbar" current transfer scheme doesn't appear to be a major issue. That said, things can get a bit balky at the extreme low end of the throttle (where it will occasionally require a nudge to get going). The mechanism also tends to be a bit "bindy" at said low throttle settings, so not quite up there in the "A" category. Pretty darned close, though. But of course, this only applies to the "good" ones (IE, if your intention is to operate one of these, don't buy unless you have guarantees about its performance characteristics).

To remove the locomotive shell, first unscrew the two small screws at the back end of the cab. Next, remove the two long screws inside of the center steam boxes. Lastly, remove the screws that connect the two pivoting steam pipes to the pipes on the shell. The shell should lift up and off at that point. Note that a wire for the headlight runs from the motor up into the boiler, so the chassis and shell cannot be completely separated (not without yoinking that wire, anyway).

Grade: B (for the ones that were put together correctly, or were recalled and repaired)