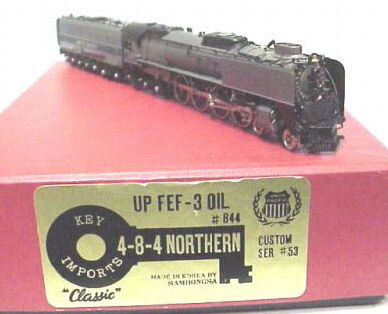

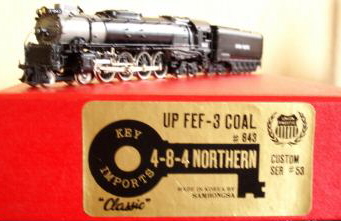

Introduced: 1987 (first run) and 2001 (second run)

The first run of these Key FEF Northerns (SER #53) included an FEF-2 (#840) and three FEF-3's (#843, #844 and #8444). The second run (SER #128) included three FEF-2's (#820, #821 and #824) and six FEF-3's (#836, #840, #841, #839, #843 and #844). Most (if not all) of these were released in both "coal" and "oil" versions.

Having never owned one of the second run 4-8-4's, I'll have to limit my discussion (for the most part) to the first run. The SER #53 chassis is all metal, although it's also fairly minimalistic (with the shell providing most of the actual heft) -

The motor is a closed-sided can (made in Japan by Sagami). Right-rail pickup is provided by the four right-side drivers. Left-rail pickup is provided by the seven left-side tender wheels. All the rest of the wheels are electrically neutral. Current is transferred from the tender to the locomotive via a stiff wire on the drawbar. Only the third pair of drivers (from the front) is geared (with the remaining drivers being turned solely by the cranks). All gearing is metal. The driveshaft is a multi-piece plastic affair that connects to the worm housing. Said housing is mounted on a leaf-spring and connected to the motor via a torque arm.

The pilot coupler (for the ones that have them) is a dummy (IE, non-operational) knuckle. There is no coupler on the tender (although a pocket and a screw are provided, so adding a Micro-Trains coupler looks to be a simple operation). The shell includes cab interior detailing. The wheels are low-profile, so no problems on Code-55 track. The drawbar has two holes - one for extreme close-coupling. As delivered, there are no traction tires. However, a TT-equipped driver set is included in the box should you wish to trade pickup for additional pulling power. A non-directional headlight is mounted inside the boiler (with a wire running back to the motor). A non-operational (IE, no lightbulb) back-up light is built into the tender. These locomotives look and operate best on 19"-radius curves and broader. I don't know what the absolute minimum radius is for curves, but they definitely can't handle 11" (where the tender will consistantly derail).

Out of the box, performance on these first run FEF's is mediocre at best. Yes, running "wheels up" on my workbench (with current applied directly to the wheels and the drawbar), the mechanism runs just as smoothly and quietly as can be. Unfortunately, none of that smoothness is evident once you actually try to run it on the rails. Overall jittery running is the rule of day (and with stalls at slow speeds being virtually inevitable).

All of the problems appear to be caused by how the tender collects current and transfers it to the engine. The centipede truck's axles are press-fit into the truck assembly, with current flowing from the axles... to the truck assembly... into the tender... out the drawbar post... and then on into that single stiff wire on the drawbar. IE, lots of potential points of failure. The tender's pilot truck is similarly problematic insofar as it's loose, floppy and barely in contact with the chassis (it's also free to rotate 180 degrees if you're not paying attention, and with a dead short being the end result) -

Despite all of the problems, the actual locomotive mechanism is a solid one. So, there is a great deal of potential here. For starters, removing the centipede truck and cleaning all of the contact points (axle mounts, chassis mounts, screws, etc) will go a long way towards improving performance on these models. Adding a small glob of solder to the drawbar wire where it inserts into the drawbar can also help. After making said tweaks to my FEF, performance improved significantly. First off, stalls are no longer a problem. And although it still runs a bit uneven at slow speeds (and with the headlight flickering along with the slight changes in speed), it's very close to being operable. I think that augmenting the drawbar wire with an actual insulated mini-wire (running from the tender to the motor) would likely solve the rest of this model's problems. Unfortunately, "as delivered", these models are pretty much useless beyond anything but sitting in a display case and looking cool.

As mentioned above, I have never owned a second run (series #128) FEF. However, I'm told by others that the tender trucks were completely reworked. First off, a washer was added on top of the pilot truck to improve conductivity (said washer also serving to eliminate excessive movement of the truck). Next, the pilot truck's screw slot was angled to allow better articulation. Also, a pin was added to the tender chassis to keep the pilot truck from spinning around and shorting out. As for the centipede truck, the axles are no longer press fit into the frame and instead have a plate to hold them in place. This allows the truck to have more of a sprung effect -

In addition to the tender changes, the single/straight drawbar wire was changed to a "U" shaped one (thus allowing it to contact the tender post at two points instead of just one). Also, the pivot point for the locomotive's pilot truck was moved forward (IE, no longer attached to the driver bottom-plate). And as one might expect, all of these changes went a long way towards improving performance in these models. Not surprisingly, Series 128 FEF's tend to sell for $100-$200 more than the Series 53's.

To remove the locomotive shell, unscrew the two small screws underneath the back end of the cab (one on either side of the drawbar post). Next, remove the screw underneath the pilot truck. The shell should lift right off at that point (just note that the headlight wire is soldered to the motor, so you won't be able to move the shell too far).

Grades: C for first run, and (I'm assuming) at least a B for the second run.