Introduced: 1996

As pictured, these models were released in two different permutations (1938 and 1940). They are extremely rare, and as of this 2015 writing are commanding premium prices on eBay ($1000+). I have never owned any of them (and probably never will), but noted N scale brass expert Max Magliaro has. His generously contributed observations are as follows -

Running Characteristics -

- Minimum Speed: 10 mph on smooth DC (15 mph with traction tires)

- Maximum Speed: 120 mph (at 12VDC)

- Current Draw: 135 mA (260mA with traction tires installed under heavy loads)

- Weight: 115g

- Headlight: Incandescent, non-directional

Construction and Disassembly -

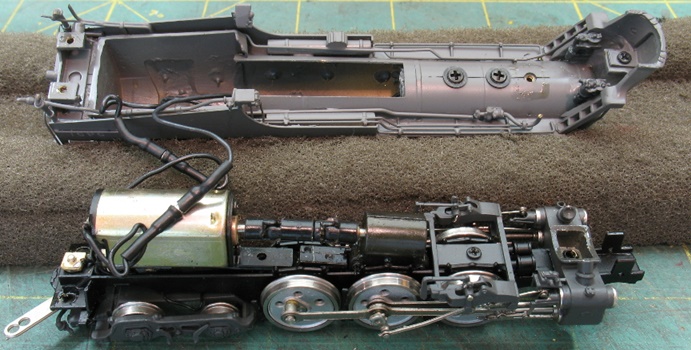

The fit and finish of the engine is excellent for the most part, although there is an issue with the valve sliders (see below). To remove the boiler shell, flip the engine on its back and begin by removing the two small Philips head screws at the rear (on either side of the drawbar connection). Next, remove the large screw through the pilot truck. Remove the screw, truck, washer, and spring, and carefully set those aside. The chassis will now pull right out of the shell (although it may take some wiggling as the fit is tight near the center).

To reassemble, note the steam pipe that hangs down over the cylinders on the left side from the shell. You must carefully get that back into its corresponding hole as you put the shell back on. Also, be careful with the headlight wiring.

Features -

The motor is a three-pole can type. It is mounted on a torque arm that is connected to the gearbox (a common Samhongsa design). The driveshaft is plastic (Delrin) with a couple of U-joint connectors. All the drivers are sprung. All the wheels are perfectly in gauge on the NMRA gauge plate. All the wheel flanges run fine on Atlas code 55 track. The headlight wiring is equipped with socket/plug connectors. As delivered, there are no traction tires. However, a replacement traction-tire driverset is supplied in the box. The tender has a mounting pad for a Micro-Trains coupler, and the engine I tested was indeed fitted with one. A #1023 will fit easily, and the coupler height is dead perfect (no shimming or filing needed).

Pickup -

Left rail pickup is from the three left-side drivers and the two left-side trailing truck wheels (the pilot truck wheels are fully insulated on both sides). Right rail pickup is from the six tender wheels. Pickup is very solid, although the spring-wire connection on the drawbar is a bit of a weak point (a common nemesis on brass steamers). I suggest either hard-wiring across the drawbar, or soldering a second spring-wire in place to form a "U" on the drawbar (thus sandwiching the pin and making for more solid contact). Yes, if you get the spring-wire adjusted just right it works well, but it will remain a nuisance until you upgrade it.

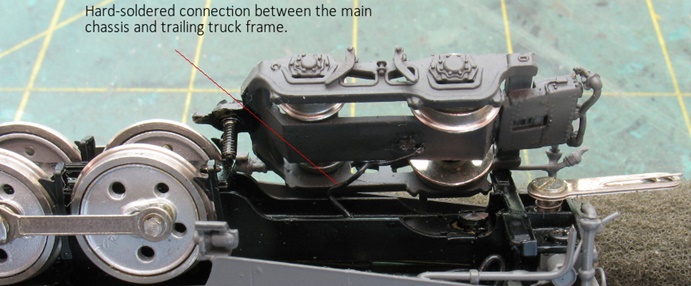

The trailing truck pickup is a bit unusual. Instead of relying on the truck tongue making contact with the frame through a screw/washer/spring, there is a fine wire hard-soldered between the truck frame and the underside of the engine frame -

Performance -

The engine runs very smoothly and quietly for the most part. It does exhibit slight "jack rabbit" starts from a stand-still, and cannot maintain smooth, even running below about 15 mph. However, once it gets moving, it runs well. The headlight is a bit dim until the engine is moving about 25 mph, but otherwise looks good. Without the traction tires the engine can pull nine Kato passenger cars on level track before it starts to slip. Unfortunately, the engine falters badly on a modest 1.7% grade (barely able to manage five passenger cars, which is hardly sufficient for the 20th Century Limited).

The engine's grip improves significantly with the traction tire drivers installed, as I was able to pull an 18-car passenger train over my test 1.7% grade without slipping. However, even with a 12-car train, the engine slows significantly on moderate hills and curves. The motor is simply not powerful enough to handle the increased load unless the operator "rides the throttle" (turning it up to maintain a constant speed). Also, overall smoothness suffers with the traction drivers installed. The rubber tires simply don't allow the drivers to slide through curves as easily, so the motion is a bit stilted at lower speeds (between 10-15 mph). However, by 20 mph it runs very well (even with the tires). Note that with the traction tires installed it is easy to pull a train heavier than what the motor is really capable of tolerating. While pulling an 18-car train, current draw rises to over 250 mA and the motor starts to get quite hot. So, I would suggest limiting the train to about 12 cars for safety.

I do not have any curves sharper than 18"-radius, but it handled those (and #5 and #7 turnouts) with ease. Judging by the swing on the pilot and trailing trucks (and the clearance between the engine and tender), my supposition is that the engine could easily negotiate sharper curves.

Aside from the underpowered motor, there are three additional problems that bear mention here -

1. Valve Sliders

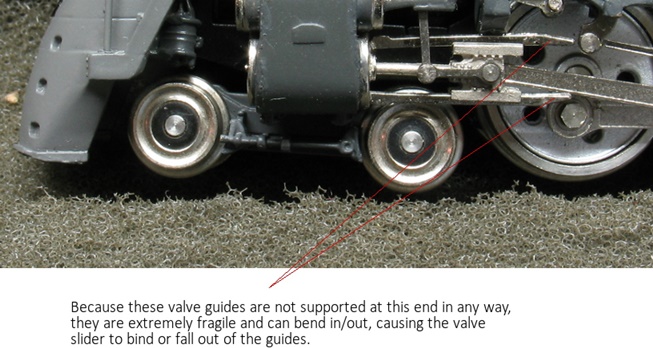

Below about 15 mph, the engine I tested had a pronounced lope once per driver revolution. This was severe enough to prevent the engine from reliably running any slower than 10 mph (although it smooths out nicely above 15 mph). The bind seems to be coming from the valve sliders and guides (see photo). The problem is that the two guides are simply brass stems that are only attached at the end that is affixed to the cylinder. As such, they are quite vulnerable to bending in/out, or closer together/farther apart (even with the most gentle handling). When they are tight, the slider binds. When they are loose, the slider can fall out and jam the engine (and even if it doesn't jam, the loose guides will allow the slider to cock against the top or bottom and cause more binding).

Some break-in running and a drop of oil on the sliders helps a lot, but this is bound to be an annoying weak point over the life of the engine. My suggestion would be to avoid handling the engine as much as possible (and never touch the valve guides at all). When I got the sliders adjusted as smooth as possible, the loping in the motion would go away, but the engine could still only sustain a minimum speed of about 10 mph.

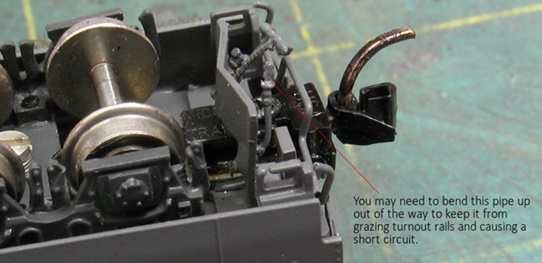

2. Short Circuit From Low Pipe

The engine I tested had a nasty short-circuiting problem caused by a low-hanging air line next to the rear coupler (with the tip of the air line coming in contact with the rails and shorting the engine as it went through turnouts). This was easily corrected by simply bending the pipe slightly upwards -

3. Dragging Pilot Wheels

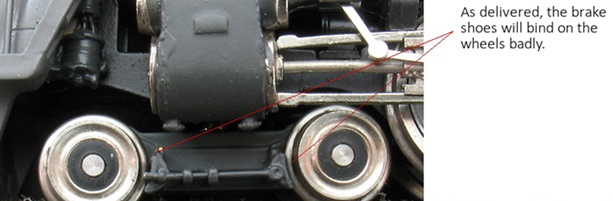

The pilot truck wheels rub on the brake shoe details so heavily that one wheel would not turn at all. This causes drag on the engine, and as the paint wears on the truck frame, it will eventually cause a short circuit.

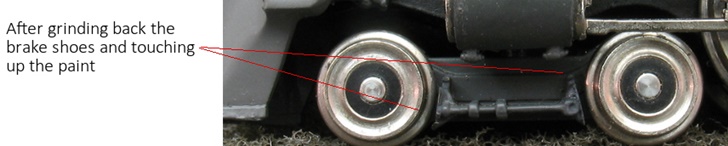

I repaired this by removing the pilot wheels from their axles and then grinding back the brake shoe details with a motor tool and grinder (a quick touch-up with some Scalecoat Grimy Black handily disguises the repair). And yes, this might cause brass collectors to cringe, but it's a case where the perfection of the detailing must be sacrificed in order to make a practical, runnable model. And although this isn't the "magic wand" to solve all of the engine's problems, it definitely ran smoother and pulled better after addressing this one issue (it could pull one full passenger car more up my test grade, and ran visually smoother at very low speeds).

Conclusions -

Overall, this is a beautiful-looking, but only fair-running model. It has sufficient weight and pickup, but even with its basic problems addressed, it could really use a more powerful motor. The motor's low power can't sustain smooth slow speed running. And with longer or heavier trains, it will need throttle monitoring from the operator to handle hills.

These engines were marketed with a matching 20th Century Limited 13-car set that is much heavier and less free-rolling than the Kato passenger cars I used for testing, so putting in the traction tire drivers is going to be a must for that train. And even then, the full 13-car set will overload the motor, so I wouldn't recommend hooking up any more than 6-8 cars at a time.

Grade: C