H-8SA -

H-9S -

H-10 w/stoker -

H-8SA -

H-9S -

H-10 w/stoker -

Introduced: 1988

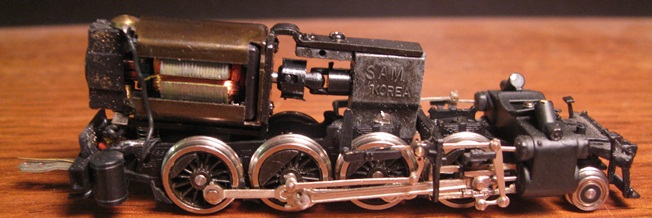

These PRR 2-8-0 models were released in three different flavors - H-8SA, H-9S and H-10 w/stoker. They all came out at the same time, so I'm going to go ahead and assume that they all share the same basic internals. The mechanism design employed here is virtually identical to the one that Samhongsa used in the SP 2-8-0's they built for Oriental Ltd in 1985 -

The chassis is all metal, although fairly light (with most of the locomotive's heft coming from its shell). The motor is an open-sided / straight-wound 5-poler (no flywheel). Right-rail pickup is provided by the four right-side drivers. Left-rail pickup is provided by the four left-side tender wheels. All the rest of the wheels and drivers are electrically neutral. Current is transferred from the tender to the engine courtesy of a stiff wire on the drawbar. As delivered, there are no traction tires. However, an ala carte TT-equipped driverset is included should you wish to swap pickup for pulling power.

A short, two-piece plastic driveshaft turns a worm inside the enclosed gear tower, which in turn drives a gear on the #2 axle. All the other drivers are turned by the valve gear. All drivers are sprung. The gear tower and motor are both spring-mounted (with a torque arm connecting the two) - an extremely sophisticated design for the 1980s! All gearing is metal. There is no lighting. A dummy (fixed / non-operational) knuckle coupler is mounted to the pilot. There is no coupler on the tender, although a Micro-Trains friendly pocket (with ready-to-go screw) is provided. Wheels are low-profile, so no problems on Code-55 rails.

Overall performance is quite solid. I had no problems operating mine around curves as sharp as 9.75"-radius, and despite the lack of traction tires, pulling power is surprisingly strong (around 20 small freight cars on level track). The mechanism runs smoothly and quietly for the most part, although it does tend to run just a bit "coggy" (herky-jerky) at creep speeds. Also, given the somewhat unreliable nature of that "stiff-wire-on-the-drawbar" current transfer scheme, stalls at the extreme low end of the throttle are pretty common. Lastly, the gearing is such that the top-end speed is quite excessive.

Minor quibbles aside though, these are beautiful models that run acceptably well. No, not quite up there in the "A" category - but awfully darned close (especially if one were to improve conductivity by running an insulated mini-wire from the tender to the motor).

Here's some additional information re speed that was provided to me by noted brass locomotive expert Max Magliaro -

Locomotive Speed (no cars) -

- @6v - 67.5 scale mph

- @10v - 111.4 smph

- @12v - 131 smph

"The high end is way overboard at 131 smph, but not the worst I've seen. Back-calculating the motor speed from the driver size (.377") and the gear ratio (27:1) shows that the motor is turning 19,712 rpms at 12v. So, a slower speed motor would do a good job of slowing this engine down without the need for an exotic gearhead or other driveline rebuild. A Mashima 1015 only turns 11,000 rpms under load at 12v, so that would cut the speed almost in half and allow the engine to run with a lot more low-speed smoothness and power."

To remove the locomotive shell, first unscrew the two small screws on the back end of the cab. Next, loosen the pilot truck screw such that you can move the pilot truck out of the way (thus revealing the chassis screw underneath). Unscrew the latter and the shell should lift right off.

Grade: B