Introduced: 2023 (analog version) and 2024 (DCC versions)

These gorgeous looking and smooth running models are available with either a Soundtraxx DCC sound decoder, a Digitrax DN163DK non-sound decoder, or no decoder at all. And do note that Kato's Big Boy is not officially "DCC Ready" and that all of the decoder-equipped models are hard-wired installs (more on that shortly).

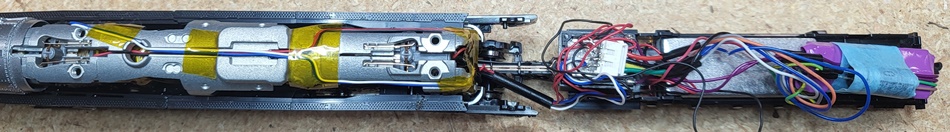

The highly detailed plastic boiler shell is divided into three main parts - top front, top rear and bottom. Once all that is removed, you will find that the inner chassis is all-metal and split-frame.

The engines are split-frame as well, with each side electrically isolated from the other. Each engine comes with its own separate flywheel-equipped coreless motor. And as demonstrated in this Kato Video, each engine is capable of riding down the rails all by itself, thus there is no driveshaft (or anything else) connecting the two engines together. Each engine has contacts at the top that transfer current to the metal chassis, thus sharing current between the two engines. The rear engine also receives current from the drawbar (and hence the tender), which is then shared with the forward engine via the chassis. Wires at the back of each motor collect current from the engine halves. A PC board connected to the forward engine provides bright white LED lighting for the headlight. As delivered, there is no coupler on the pilot. However, an ala carte coupler-equipped pilot is included in the box should you want to make the swap.

Pickup is provided by 12 of the 16 drivers. Each engine has one driverset that is equipped with traction tires. The pilot and trailing trucks are electrically neutral. The pilot truck is equipped with a spring, but it's pretty weak and ineffectual.

Additional pickup of the low-friction ilk is provided by 8 of the 14 tender wheels (the inner six wheels are electrically neutral). A pair of stiff wires inside the drawbar transfer current to the rear engine. The drawbar is snap-fit in place and easily disconnected. The wheels are blackened and low-profile (IE no problems on Atlas Code-55 rails). Note that there is no backup light in the tender (ala Kato's FEF 4-8-4). The tender coupler is a standard Kato knuckle mounted on the rear truck.

Each engine has one geared axle (the one with the traction tires). All gearing is plastic. The axles are held in place by brass bearing blocks that seat inside of cutouts in the engine frames.

The decoder installations are... well, let's just that say they're a bit of a mess and probably not a major source of pride for Kato. The original scuttlebutt was that these installations were going to be done at Kato's factory in Japan. However, looking at the results I find it hard to believe that that was the case. My guess is that some (or all) of these were hurriedly whipped up at Kato USA's HQ in Illinois. Note that they did include a capacitor (220 uf / 25v) as part of the sound decoder installs.

As noted above, I would not categorize these models as being anywhere near "DCC Ready". IE, you're going to need to completely disassemble the locomotive in order to hardwire the motors and headlight to a decoder. The only slight nod Kato made towards DCC friendliness is the fact that they provided skinny little channels in the chassis as a place to run wires to the two motors.

These are terrific looking models with performance to match. Mine runs silky smooth and whisper quiet at all throttle settings. It's strong enough to pull fifteen pounds worth of weight (hey, seeing is believing). And with so many wheels providing pickup, this thing will never stall out. I crept mine around my torture test layout (with its insulated frog turnouts and filthy track) at speed step 1 and didn't have a single hiccup. The minimum radius for curves seems to be 11" (mine derails on 9.75" curves). OK, no, I'm not thrilled about the lack of DCC readiness or the sloppy decoder installation, and I'm never a fan of traction tires. But I certainly can't argue with the end results. These are absolutely sensational runners and certainly on par with Athearn's equally excellent Big Boy model.

Prototype -

The 4-8-8-4 Big Boy is an articulated Steam Engine manufactured by the American Locomotive Company between 1941 and 1944. The Union Pacific was the sole purchaser of these engines, owning and operating a total of 25 of the colossal 600 ton engines. The 4-8-8-4 wheel arrangement combined stability and power, with the four wheel leading truck allowing for smoother entry into curves while the two sets of 8 drive wheels provided 135,375 lbf of tractive force. The trailing four axle truck helped support the large firebox that was needed to keep the massive engine fed. The original Big Boy engines were coal powered, with 4014 being converted to oil when it was rebuilt after its retirement to be used in excursions.

The Big Boys plied the rails as reliable workhorses until the final unit was retired from revenue service in 1959, with eight engines surviving today. While most of the survivors are static display pieces, unit 4014 was re-purchased in 2014 by the Union Pacific and rebuilt in a five year process that brought it back into service as the largest, most powerful operating steam locomotive in the world, touring in 2019 and again in 2021 to celebrate the history of America's transcontinental railroads and the Union Pacific's commitment to preserving its history.

Locomotive Features -

- Dual coreless motors with brass flywheels for unmatched pulling performance

- Weights carefully placed along the body even in the cylinders to give the engine perfect balance and weight distribution.

- Minimum radius 11" (282 mm)

- Operational tinted LED headlight

- 4014 has the iconic "Big Boy" chalk lettering on the front of the smokebox

- 4014 is built to match the 2021 Excursion tour appearance: Oil Tender, Graphite Firebox, Silver cylinder head and piston covers, Builder’s Plate

Shell Removal -

Using the parts diagram from Kato's website as your guide, start by pulling the cab off of the shell (simple friction holds it in place). Next, unclip the forward and rear domes from the top of the boiler shell to reveal the four screws that hold the shell in place. Remove them. Next, remove the smokebox front (once again, held in place solely by friction). This will free up the fronts of the handrails. Next, pop the handrail stanchions out of the forward (graphite) portion of the boiler shell. The rear portion of the shell should now lift off. And sorry, that's as far as I'm willing to go with mine. Good luck getting at those engines in order to wire up a decoder!

On the plus side, the tender shell is easily removed - simply pry one of the sides away from the chassis and it should pop right off.

Grade: A (with my caveats re DCC hostility)

(Thanks for the photos Peteski!)