Introduced: 1984

These Hallmark U50's are surprisingly hard to find. They rarely show up on eBay, and when they do they sell for premium prices (generally around $500 as of this 2009 writing). My theory (based on nothing other than my own conjecture) is that this is one of the few old brass models that people actually buy to run on their layouts. Proof, you ask? Well, these U50s (like the rest of Hallmark's diesels) did not come with any sort of factory-installed couplers. However, I have yet to encounter a single brass U50 on the secondary market that didn't have after-the-fact Micro-Trains couplers installed on it. QED - people bought 'em to run 'em. And given the strikingly unique prototype, I guess that should come as no surprise.

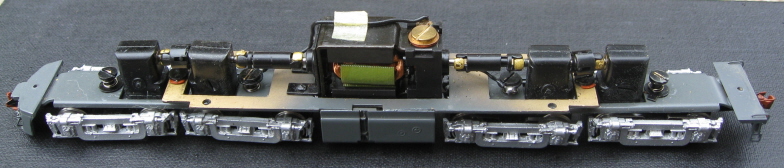

The mechanism follows the basic 1980s Samhongsa diesel design, just doubled (vis'a'vis the trucks) -

The chassis is a thin and flimsy slice of brass (with most of the locomotive's actual heft being provided by the brass shell). The motor is an open-sided, straight-wound 5-poler. Pickup is divided fore and aft, with the forward pair of trucks picking up one rail and the rear pair picking up the other. Each pair of trucks is screwed to a thin piece of brass separate from the chassis (IE, free to pivot along with the trucks). Wheel-top wipers transfer current from the wheels into the the truck assemblies, which in turn route current into said thin pieces of brass via screws. Finally, wires conduct current from each screw-top into the motor contacts (one wire for each truck pair).

The motor is equipped with dual plastic driveshafts that connect to the worm-gear towers of the inner trucks. The inner worm gear towers transfer motion to the outer towers by way of really short plastic driveshaft clips. All axles are geared and all gearing is metal.

Micro-Trains friendly coupler pockets are provided on the swiveling pieces of brass to which the trucks are screwed (IE, not attached to the shell - ala the prototype). There is no lighting (although a non-opertional beacon detail lurks atop the cab). There is no window glazing. Wheels are low-profile, so no problems on Code-55 track.

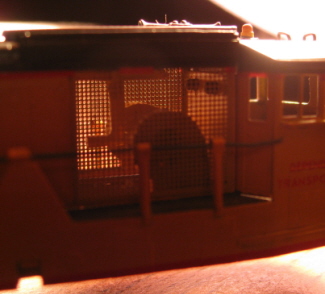

Interestingly enough, blower detailing is visible through the see-through fore and aft vent screens (a level of detailing I've yet to encounter on any other brass model) -

Performance is just OK. On the plus side, throttle response is nimble, pickup is solid, slow-speed creep is decent, the top-end speed is reasonable, and derailing is not a problem. On the down side, this model is pretty much useless on curves sharper than 11"-radius (where it will instantly derail). And even 11" is pushing it. I'd say that 19"-radius is pretty much your realistic minimum here.

Further down the down side, there's just no getting around the fact that these things are really noisy (like electric razor noisy). Mixing a big hollow brass shell, metal gears, and swiveling worm-gear towers is basically the trifecta of noisousity. From creep speed to full throttle, these things buzz like a hornet's nest. And through curves? An angry hornet's nest.

So, kind of a mixed bag here. The technology is hugely dated, and it sounds like hell. Yet, it looks great, it runs decently, and it's a model of a unique and desireable prototype. What say we just call it a "B with caveats" and get on with our lives?

Removing the shell is simply a matter of unscrewing the four tiny screws that hold it to the chassis (look for them next to the outer wheels of the inner trucks). The shell should lift right off at that point.

Grade: B (just because I'm feeling generous)