Introduced: 2015

As pictured above, these models are available in two different versions - "Traditional" and "Modernized".

According to GHB, all of their L1's were originally delivered from China with a number of rather dire factory defects. Making matters worse, GHB didn't bother to inspect/test any of them prior to shipping them out to distributors, so the toothpaste was well and truly out of the tube by the time GHB finally did get around to initiating a full-scale recall. One major online retailer (Factory Direct Trains) decided to wash their hands of the whole affair and skipped the recall process entirely (instead opting to simply dump their remaining stock of 80 units on the market at wholesale prices).

The laundry list of problems with the original release is extensive -

- All of the motors are wired backwards (IE, put them on the track with another/different locomotive and the two will run in opposite directions)

- The tender truck pickup contacts are too stiff, with the end result being wheels that roll poorly (or not at all)

- The tender truck springs are too large/stiff (thus interfering with the trucks' ability to pivot)

- The driver bottomplate has a gear bulge that hangs down too far and actually hits the crossrails on turnouts (resulting in the

locomotive getting hung up with its drivers spinning)

- The wheel flanges are slightly oversized (IE, they will not run on Atlas Code-55 rails)

- The gauging on the wheels is a bit tight (resulting in problems through turnouts)

- Assorted assembly/QC problems (varying from one model to the next)

For those who purchased models prior to the recall, GHB will replace them with the "repaired" version (excluding those who bought the dumped models - those folks are on their own).

I was one of the "lucky" few who bought one of the models from the original release, and I can certainly attest to the fact that they are completely useless. Hell, the wiring was so screwed up on mine that it barely ran at all. So, if you're thinking of purchasing one of the dumped models (and I will admit, the prices make it very tempting), just know that you're going to have to put a lot of work into it before it will run properly. Then again, the repaired/revised models aren't all that great either, so chances are you're going to wind up having to expend a good deal of effort regardless of which version you start with.

Anyway, onward with the review (now focusing on the post-recall revised/repaired version) -

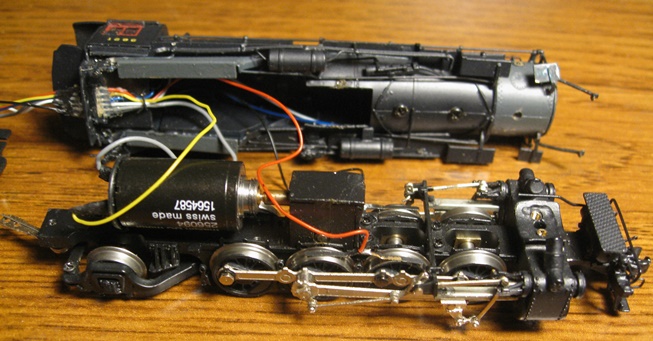

The engine chassis is all metal and basically just a skeleton (with the boiler shell providing most of the model's heft). The motor is a coreless Maxon (#256094). The motor and worm box are firmly mounted to the chassis (no sprung torque arm or anything like that). A short metal driveshaft runs from the motor into the worm box (no flywheel).

Driver pickup is provided by wired wheel-wipers that contact the tops of the #2 and #3 driversets (the forward and rear driversets are electrically neutral, as are the pilot and trailing trucks). An LED-equipped PC board for the directional headlight is mounted inside the boiler shell. The chaotic wiring for the headlight, motor and driver pickup meet at a six-hole socket mounted at the back of the shell. A six-pin wiring harness/plug connects to said socket, thus routing the wiring back inside the tender -

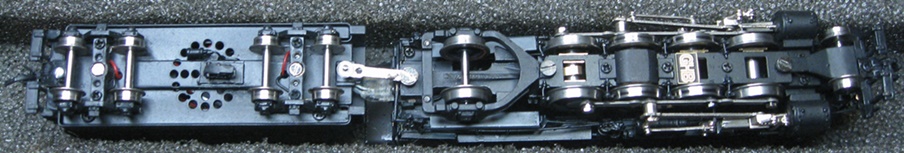

The driver axles seat inside of brass bearing blocks firmly mounted inside of cutouts in the frame (IE, no springs). Only the #3 axle is geared (with all the rest of the drivers being turned solely by the running gear). All gearing is brass. As delivered, there are no traction tires on any of the drivers (although oddly enough, a number of ala carte traction tires are supplied in the box - completely useless since none of the drivers actually have grooves in which to accommodate them). A fixed/non-operational knuckle coupler (of unknown origin) is screwed to the underside of the pilot. Both the pilot and trailing trucks have metal spring-arms providing downward pressure on the axles. The wheels are properly gauged and low-profile (no problems on Atlas Code-55 rail) -

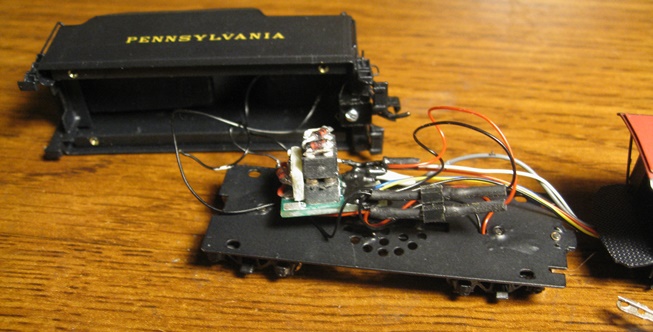

The tender is... well, it's pretty pathetic. The drawbar actually has an old-school current-conducting wire on it (a bit of a headscratcher since it doesn't actually conduct current). A clear plastic washer on the tender drawbar post helps keep the drawbar hooked up to the tender. The wiring to/from the engine is sloppily soldered to a PC board inside the tender. As delivered, said board comes all wrapped up in electrical tape (temporarily removed here for photo purposes). Said PC board is also mounted to sweet bloody nothing, so basically it just floats around in there in it's little rat's nest of wires -

On the plus side, the board is equipped with a standard 8-pin NMRA-style DCC socket. Additional wiring from the main board runs up to a directional backup light LED board mounted inside the tender shell. Still more wiring runs to the truck pickups (this wiring is equipped with socket/plug connectors, whereas the backup light wiring is not). As with the drivers, wired wheel-top wipers provide the pickup (with all eight wheels being wiper-equipped). A Micro-Trains coupler is provided on the tender shell. As pictured, speaker holes are provided in the chassis.

Note that the LED's for the headlight and backup light are yellow/orange (as opposed to the "golden white" originally advertised by GHB).

Given some of its more primitive features (EG the wired wheeltop wipers), performance is just so-so. Mine runs relatively smoothly at most throttle levels, but it does tend to be a bit jittery at slow speeds (particularly through insulated-frog turnouts). It's also a bit noisy (emitting a distinctive buzzy growl when pulling a heavy load of cars). On the plus side, pulling power is respectable (around 30 cars on level track) and the top-end speed is quite realistic. I'm not sure what the minimum radius is for curves, but my guess would be somewhere in the 13-15" range (the tender consistently derails on 11"-radius curves or sharper).

The main running issue I encountered with mine is its performance at low voltages. The mechanism seems to be a bit bindy, so it takes about 50% of my throttle just to get the thing moving (at which point it will lurch forward at about 15 SMPH). And although once moving you can back off the throttle a bit, it'll eventually stall out at anything much below 40%. So, no, not particularly well suited to delicate switching operations.

The other glitch I encountered with mine is that it would consistently derail on one of my left-handed Kato Unitrack turnouts. And although I spent a good long time trying to figure out what was causing the problem, I never could pin it down. What I wound up doing instead was simply replacing said turnout with a new one, at which point all of the problems magically went away. So, I guess there was something a bit off with that particular turnout (although none of my other locomotives ever had any problems with it). It could just be that the L1 is a bit more finicky about wonky track than most locos.

All of that said, the real deal-breaker for me is the amateurish wiring. The soldering is very fragile and poorly executed (particularly on the plug/socket connections at the back of the engine). Adding insult to injury, all of the solders are slathered in some sort of silicon goop, making it extremely difficult to get in there and fix the inevitable failures. So, although the idea of making this thing DCC-Ready was a laudable goal, the execution leaves much to be desired. Frankly, I think things would've turned out much better if they'da just applied the KISS principle ("keep it simple, stupid").

Features -

- Two different versions - "Traditional" and "Modernized" (4 road numbers each)

- DCC-Ready (8-pin NMRA socket in tender)

- Maxon Swiss motor

- Tender floor drilled with speaker holes for sound

- Authentic PRR paint and lettering schemes

- LED headlight and reverse light

- Constant intensity directional lighting

- Detailed locomotive cab and boiler backhead

- Locomotive cab windows with glazing and curtains

- Separately applied details such as brass bell, grab irons, ladders, etc.

- Hinged cab deck plate (apron) between locomotive and tender

- Tender coal load

- Drawbar with two holes for prototype and long coupling

- Factory-installed painted engineer and fireman figures

- Electrical pickup on locomotive and tender wheels

- Sufficient locomotive weight to pull 30 N scale freight cars

- Micro-Trains #1015 coupler on the tender

- Two-piece box with sponge foam inserts

- List price - $750

- Limited production run (around 200 units)

To remove the locomotive shell, first unscrew the two screws on the back of the cab (near the bottom). Next, remove the pilot truck. Once that's out of the way you will see the hex bolt that holds the front of the chassis to the boiler. Use the included hex driver to remove that and the shell should lift off (just be careful with all of the wiring).

To remove the tender shell, unscrew the four screws (one on each corner) on the underside of the chassis. The shell should lift off at that point (but once again, be careful with the wiring).

Grades: D (for the revised/repaired version) and F (for the original version)