Introduced: 2004

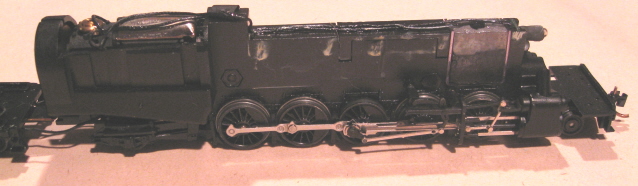

This USRA 2-10-2 was the first steam locomotive produced by Con-Cor without the aid of Kato. And although a decent looking model, Con-Cor did take a few liberties with some of its dimensions (relative to the prototype). First off, the drivers are spaced a little farther apart than they need to be (resulting in the overall wheelbase being about 1/16" too long). Also, the entire boiler is about 3/16" longer than it should be (and somewhat too wide as well). Now, I've never taken much notice of these minor inaccuracies myself (let alone been bothered by them), but it does seem to annoy some people (y'know, the rivet counters of the world). On the other hand, this model has same fairly dire performance issues that I do find annoying (but more on all that in a moment).

The split-frame chassis is all metal and quite hefty (weight is provided in the boiler shell as well). The motor is an open-sided / skew-wound 5-poler. A small flywheel is mounted to a short driveshaft out the back side of the motor. All ten drivers are geared and all gearing is plastic. Pickup is provided by eight of the ten drivers (the rearmost set being equipped with traction tires). All eight tender wheels provide pickup as well. The pilot and trailing trucks are electrically neutral. The center driverset lacks flanges. Small PC boards provide directional lighting (one mounted to the front of the locomotive chassis and one mounted inside the tender). Unfortunately, the bulbs are not LEDs. Operational Micro-Trains couplers are mounted on both the pilot and tender chassis. All wheels are blackened and low-profile (no problems on Code-55 rails).

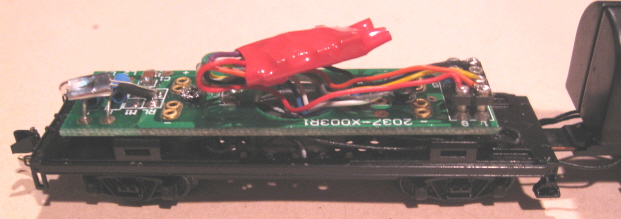

This locomotive is fully DCC-Ready, coming with a handy 8-pin NMRA DCC socket in the tender. Speaker holes are provided in the bottom of the tender should you wish to install a sound decoder (two additional plugs are provided for connecting speakers to the PC board) -

This model is tantalizingly close to being something pretty darned special. Unfortunately, as delivered it doesn't quite cut it in the performance department. Yes, when it's running, it runs really well. The crank action is smooth, throttle response is excellent, slow speed creep is sensational, and the whole thing runs as quiet as a church mouse. Better still, it pulls like a horse.

However, the bad news with this thing is the pickup - or lack thereof. Yeah, you'd think that with power coming into the mechanism from sixteen different wheels, stalling would be a non-issue. Unfortunately, that's simply not the case - and it's the tender trucks (particularly the forward one) that are the weak link. Here's the deal - to accommodate DCC, power is not routed directly from the locomotive chassis to the motor (or to the headlight, for that matter). Rather, current flows from the drivers, into the chassis, into the drawbar (via two stiff wires), into the forward tender truck, into the tender PC board and, finally, to the motor and headlight (by way of a quartet of flexible wires).

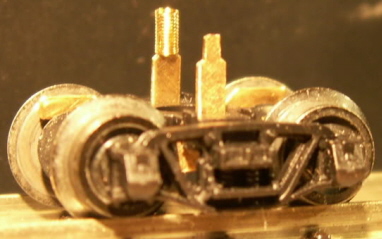

Consequently, if that forward tender truck isn't doing it's job reliably, you've basically eliminated pickup from twelve of the sixteen wheels. And sadly, chances are that it isn't doing its job reliably. Current is transferred from the tender trucks into the tender by way of four sticky-uppey wipers (which, in theory, should be pushing firmly up against long thin contact strips inside the tender). Unfortunately, said truck wipers are completely unreliable vis'a'vis their ability to maintain continuous contact with the tender strips - IE, get any kind of sway or rock going (oh, like through a turnout) and you're looking at a stall. Even small dips and bumps in otherwise straight and level track can cause your 2-10-2 to come to a lurching halt.

Fortunately, there are a couple of relatively easy solutions to the conductivity issues. First, simply adding more weight to the tender will go a long way towards improving performance (thankfully, there's a lot of open space available in there). Taking things a step further, attaching small springs (Micro-Trains #1952 coupler springs, for example) to the tips of the tender truck wipers will give them a bit of flexibility as well as extended reach. Using a Dremel grinding wheel to slim down the tips makes the whole task a quick and easy one -

Another problem with at least some of these is that they will occasionally (and inexplicably) derail on curves. The problem here is that the inner plastic axles on the drivers are a slightly smaller diameter than the metal axle "nubs" on the backs of the wheels (resulting in a small ridge where the two join). Depending on the individual model, these ridges can cause the axles to get hung up as they slide back and forth through the bearings (and thus cause the drivers to derail). From what I'm told, the possible fixes for this particular issue are either difficult, expensive, or both.

So, ultimately kind of a mixed bag here. If you enjoy tinkering, this locomotive has a lot of potential. But if not, yours will likely wind up gathering dust on a display shelf.

To remove the locomotive shell, simply spread the shell sides apart back by the cab. It should slide up and off quite readily at that point - just make sure to slide it forward a bit before lifting (to clear the headlight). To remove the tender shell, find the seam between the shell and the chassis and spread the shell sides apart a bit. It too should slide up and off easily.

Grade: D

Reviewed: 01/05 Model Railroader ("Con-Cor's USRA 2-10-2 is a big steam locomotive designed for mainline freight service. Even in N scale it's an impressive machine with a long rigid wheelbase that'll look its best on large-radius curves... Con-Cor's model is a fine replica of its prototype. It closely matches the major dimensions shown in USRA drawings... Manufacturers always face clearance problems in steam locomotive mechanisms because model wheel flanges are oversize. To resolve this problem, they either reduce the driver size or increase the axle spacing to provide operating clearance. In this case, Con-Cor kept the proper scale 63" driver and stretched the rigid wheelbase a scale 28". Additional clearance is also necessary around the pilot and trailing trucks. All of the 2-10-2's modifications are done in small increments that up to about a scale 40" in the model's overall length. However, these adjustments are spread out and well concealed...

"The die-cast metal chassis is driven by a five-pole skew-wound motor mounted in the firebox and cab. The two-part frame is electrically split so all of the drivers and tender wheels pick up current. All of the wheelsets have been chemically blackened, and they match the NMRA gauge. The middle set of driver is blind (no flanges), and the others provide some lateral motion so the model can run on curves as sharp as 11" radius. The upper parts of the model are plastic castings with excellent boiler bands, piping, and rivet detail. The tender is a USRA standard long version with four-wheel Andrews trucks. The tender floor is cast metal with provisions for mounting a small speaker. A PC board holds the directional lighting diodes and an NMRA standard 8-pin receptacle for easy conversion to DCC. The tender has space to carry a concealed decoder. Our sample came smoothly painted black with sharply printed Illinois Central initials on the cab and numbers on the tender. The back of the tender also includes to correct tender-capacity lettering. Micro-Trains couplers are mounted at the correct height on both ends. The 2-10-2 seemed a little stiff at first, but it quickly warmed up and ran smoothly at freight speeds. Its full throttle speed is in the passenger range, but it looks much better plodding along with a drag freight. The 2-10-2's traction tires deliver enough tractive effort to pull about 54 cars... It's a good-looking model that performs well. ACL, B&LE, CG, CB&Q, C&S, Erie, IC, MP, PRR, SP, UP, Undec. $329.98")