Introduced: 2018 (Paragon3 version), 2020 (revised Paragon3 version), 2022 (Paragon4 version) and 2023 ("Stealth" version)

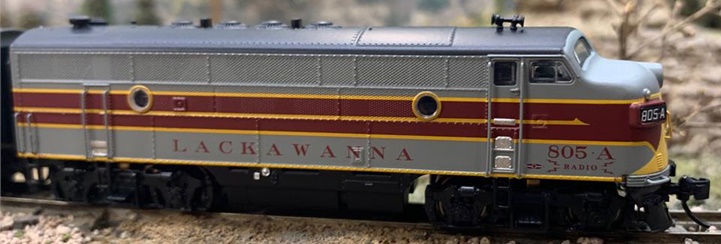

These models (deignated by BLI as "F3 Phase 2A" and "F7 Phase 1") are sold individually or in A/B sets (with the B units being non-powered dummies). The powered units are available with or without factory-installed "Paragon" DCC-Sound decoders and support for BLI's "Rolling Thunder" external sound system (the so called "Stealth" versions are simply DCC-Ready). Like the rest of BLI's diesel lineup, these are very nice looking models (for the most part). However, performance can be a bit problematic (more on that in a moment).

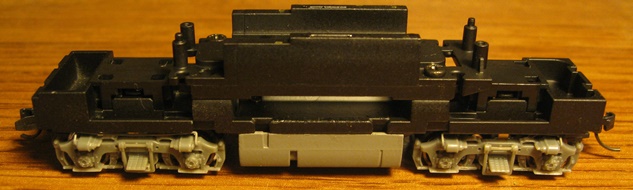

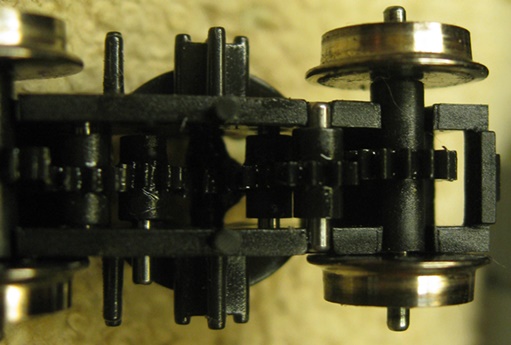

Internally, these models share a (more or less) similar design to other BLI diesels of similar vintage -

The chassis base is a flat chunk of metal (to which everything else attaches/screws). A large metal bracket (under which is found the motor and drivetrain) screws to the top of the chassis base. The motor is an open-sided 5-poler with skew-winding (held in place by a plastic saddle that sandwiches between the two metal chassis pieces). Each motorshaft is equipped with a small brass flywheel. Plastic driveshafts connect the flywheels to the brass worms which are mounted inside of plastic brackets clipped to the top of the chassis base. Bearing blocks are slotted into said brackets (one on each side of the worm). "A" units have a plastic cab interior detail clipped to the forward worm bracket. A plastic fuel tank detail is clipped to the bottom of the chassis.

For sound-equipped models, the decoder board is screwed to the top metal bracket. The Stealth versions have a Next18 DCC interface on the DC motherboard. And oh boy, wires wires everywhere - wires from the pickup contact strips, wires to the motor, wires to the speaker, and wires to the headlight/mars light/numberboard LED board. The LED board is mounted on a plastic bracket that clips to the front of the chassis base (F0 controls the headlight and numberboard lights, whereas F7 controls the mars light). All wiring to/from the decoder board is connected to plugs that plug into sockets on either end of the decoder board. The large blue wire is the antenna for the "Rolling Thunder" sound system (held in place with a piece of tape and insulated from the decoder board by a piece of bubble wrap). The speaker is rectangular and mounted inside of a plastic shroud that loosely mounts to the back of the chassis base.

The trucks clip inside of the plastic worm brackets and pop on and off easily. The truck sideframes have a number of separate press-fit detail parts. Pickup is provided by all eight wheels. The axle-ends insert into holes (as opposed to dimples) in the axle wipers. On the Paragon3 version (pictured below), extensions off the top of the axle wipers transfer current to wired contact strips mounted inside the chassis base. Starting with the Paragon4 version, the chassis wipers were jettisoned and replaced instead by wires running directly from the axle wipers to the decoder board).

Powered "B" units are the same as "A" units in most respects. However, the chassis base is different (squared off at the front rather than rounded). And as one would expect, there is no LED board or cab interior -

The chassis for the non-powered "B" units consists of the two metal parts (base and top bracket) along with the plastic worm brackets (needed so that the trucks have something to clip to). The upper metal bracket can be safely removed (to reduce the model's weight and make it less of a boat anchor) -

The wheels are blackened and low-profile (no problems on Atlas Code-55 rails). There are no traction tires. All four axles are geared and all gearing (apart from the worms) is plastic. All of the gearing comes rather heavily lubricated (or at least it did on mine). Couplers are MTL 1015's. Except for the forward coupler on "A" units, all are truck-mounted (screwed to the plastic truck sideframe/bottomplate piece). The front couplers on "A" units are screwed to the chassis.

The shell is plastic with numerous separate detail parts (horns, handgrabs, diaphragms, windows, headlight lenses, numberboards, etc) -

The DCC sound on these models is quite impressive (hey, at these prices it'd better be), although the default CV settings for volume may be a bit louder than most people will want (setting CV 133 to something between 0 and 128 will adjust the master volume). All the various sounds are advertised as being "authentic" and, as far as I can tell, they are (not that I'm any kind of expert, mind you). The enclosed speaker makes for nicely beefy sound affects (or at least as beefy as you're ever likely to find in something this small). And being "dual mode", these locos should run (and sound) the same on both DC and DCC layouts. However, non-DCC users will need a special add-on widget (pictured below) to take advantage of the non-automatic sound features (ringing the bell, blowing the horn, etc).

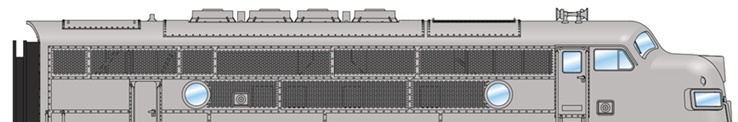

I'm told that the F3 shells from the first production run have a rather glaring error; namely, that the top grill is flipped and thus a mirror image of what it should be.

This gaffe was corrected in the second (2020) production run -

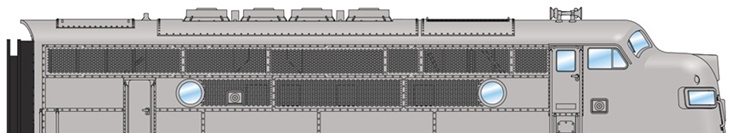

The second run of F3's also included an all new vent configuration option (representing a later version of the F3) -

Internally, models from the second production run are basically identical to models from the first run (with the only noteworthy differences being that the bubble wrap and hockey tape are gone and the blue antenna wire is now black) -

Depending on when a given model was made, performance can vary considerably. I (and others) had a lot of problems with models from the first production run, the worst of which relates to the secondary (non-axle) truck gears. The problem here is that the metal shafts that hold these gears are very loosely seated in the sides of the gearbox and can actually slide out of their little holes (thus allowing the gear to spin eccentrically). The net result of this is reduced pulling power and a lot of noise when things inevitably get out of whack. I've even had the top gears (the ones turned by the worms) lose gear mesh, thus transforming entire trucks into useless lumps of plastic (this is reportedly caused by the plastic lids that clip to the tops of the worm gear boxes popping loose).

In addition to the gear problems, I also had a lot of pickup problems with mine (despite herculean efforts vis'a'vis wheel and track cleaning, I couldn't get them to run for more than 15 minutes at a time without stuttering and stalling). The decoders were a bit flakey as well. For example, my A unit would inexplicably slow down to a virtual stop and then speed back up for no apparent reason. Worse still, the decoder in my B unit completely failed after only an hour's worth of run time. Now, I'm not saying that they're all this bad (I've certainly heard from plenty of people who didn't have any problems at all with theirs). But I do think there were enough problems to warrant a lot of caution when purchasing models from the first production run.

The good news is that models from the second production run appear to be much more reliable. The one I tested was a bit balky at first (occasionally stalling out) and pulling power was wholly unimpressive (it could barely pull its dummy B unit and twenty assorted 40' freight cars). However, after a few hours of break-in running, all of the balkiness went away and pulling power improved considerably (up to forty-plus cars). I went on to run it for 48 hours straight without a single issue, so that's a keeper as far as I'm concerned. It runs smoothly and quietly at all speeds, slow speed creep is first rate, and the top-end speed isn't too crazy. Throttle response is excellent and I haven't had any problems with any of the wheels derailing (even on curves as sharp as 9.75" radius). I guess my only concern is its rather light weight (2.7 oz), but I can't really argue with 40 cars worth of pulling power (which always seems like plenty to me). However, people wishing to pull long NTrak style trains (50+ cars) will likely want to invest in a powered B unit (or go with IMRC F's, which weigh twice as much).

Prototypes -

EMDs F3s began showing up on the rails just as World War II was ending. As the wartime restrictions were being lifted, a tremendous burden was placed on the railroads as economic prosperity began to take off across the U.S. The days of the glorious steamers were numbered as many railroads were in dire need of motive power replacements. Add the economic advantages the F3s offered to the railroads, and the rest is history. Progress is always served. The 1500 horsepower F3s were remarkably proficient at both heavy freight as well as fast-passenger service. With a body design that defines what many consider to be the most attractive diesel ever produced, the F3 offered a large canvas for the wonderfully imaginative and colorful paint schemes that many railroads proudly utilized to show off their passenger trains. EMD was to build 1107 A units and 694 B units before production was changed to the newer F7s in February of 1949.

The F7 was the fourth model in GM-EMDs successful line of F unit locomotives, and by far the best-selling cab unit of all time. In fact, more F7s were built than all other F units combined. It succeeded the F3 model in GM-EMDs F unit sequence, and was replaced in turn by the F9. Final assembly was at GM-EMDs La Grange, Illinois plant or GMDs London, Ontario facility. The F7 differed from the F3 primarily in internal equipment (mostly electrical) and some external features. Its continuous tractive effort rating was 20% higher (e.g. 40,000 lb (18,000 kg) for an F7 with 65 mph (105 km/h) gearing, compared to 32,500 lb (14,700 kg) for an F3 with the same gearing.) A total of 2,366 cab-equipped lead A units and 1,483 cabless-booster or B units were built. (Note: the B unit is often referred to as an F7B, whereas the A unit is simply an F7. For clarity, BLI refers to A units as F7A.) Many F7s remained in service for decades, as railroads found them economical to operate and maintain. However, the locomotive was not very popular with yard crews who operated them in switching service because they were difficult to mount and dismount, and it was also nearly impossible for the engineer to see hand signals from a ground crew without leaning way outside the window. As most of these engines were bought and operated before two-way radio became standard on most American railroads, this was a major point of contention. In later years, with the advent of the road switchers such as the EMD GP7, F units were primarily used in through freight and unit train service where there was very little or no switching to be done on that line of road.

Model Features -

- ABS Body with Heavy Die Cast chassis for maximum tractive effort

- Two Operating MicroTrains #1015 or Compatible Couplers

- Separately Applied Handrails, Ladders, Whistle, and Brass Bell

- Will Operate on Code 55, 70, and 80 Rail

- Recommended Minimum Radius: 9.75 inches

- Paragon Sound & Operation System featuring Rolling Thunder with authentic sounds and prototypical operation in both DC and DCC environments

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight, Mars Light

DCC/Sound Features -

- Operates in DC & DCC (use DCMaster for DC sound)

- Record & Play Operation - Records and plays back sounds and movements once or repeatedly for automatic operation

- 16-bit Sample Rate for exceptional high frequency sound clarity

- Alternate Whistle / Horn where applicable for locomotive with air horn and steam whistle - both the main whistle and alternate can be easily played

- Adjustable bell ringing interval for faster or slower bell

- Numerous user-mappable functions with available keys

- Passenger Station Ambient Sounds - Controlled with Function Key

- Freight Yard related radio chatter - Controlled with Function Key

- Lumber Yard Ambient Sounds - Controlled with Function Key

- Farm related radio chatter - Controlled with Function Key

- Crew Radio Communications - Controlled with Function Key

- Maintenance Yard related radio chatter - Controlled with Function Key

- Demo Mode for display and demonstrations

- Simple Programming with Integral DCC Decoder

- Individually adjustable sound volumes for most effects

Trivia - BLI's F3B and F7B shells are reportedly a good fit for Kato F3/F7 chassis (a good way to power a dummy B unit).

Shell Removal -

Four little plastic "claws" molded into the inside of the shell clip into small indentations in the chassis. So, to remove the shell simply spread the sides apart a bit to free up the claws. The shell should come off readily at that point (on "A" units you will also need to finagle the front coupler through the hole in the pilot).

Grades: F (for the 2018 production run) and A (for subsequent production runs)