Introduced: 2017 (Paragon3 version), 2018 (new motor), and 2024 (Paragon4 and Stealth versions)

BLI's AC6000CW was that firm's first N scale model to feature support for their "Rolling Thunder" sound system. Said system consists of a large external subwoofer-type speaker and a receiver that locomotives talk to via radio signals. I've personally never witnessed the Rolling Thunder system in operation, but I guess its purpose is to reproduce the beefy low-frequency sounds that tiny internal locomotive speakers simply cannot render.

These are very nice looking models, with crisp paint and fine detailing -

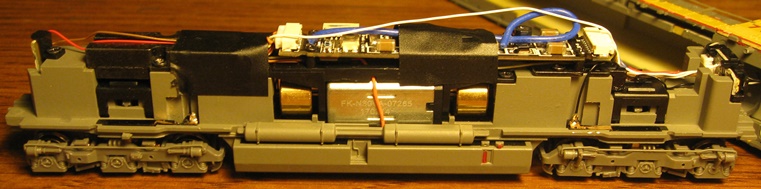

Apart from the fact that the chassis is one big hunk of metal (IE not split-frame), these models don't have a whole lot in common with any of BLI's previous diesel models (E7, E8, PA, etc). The motor used in the first production run is a closed-sided can, so I can't really comment on its internal specifications (all BLI has to say about it is that it's "powerful"). Each motorshaft is equipped with a smallish flywheel. The plastic driveshafts have hex ends on the flywheel side and plastic ball-with-pin / notched-cup U-joints on the wormshaft side. The brass worms mount between bearing blocks that seat inside of slots in the chassis (held in place by plastic clips).

Starting with the second production run (2018), the motor was changed to an open-frame type (5-pole, skew-wound) -

All six axles are geared and all gearing is plastic. The wheels are blackened and low-profile (no problems on Atlas C55 track). Two speakers are provided for DCC-Sound (mounted inside the fuel tank). The couplers are chassis-mounted Micro-Trains 1015's. There are no traction tires.

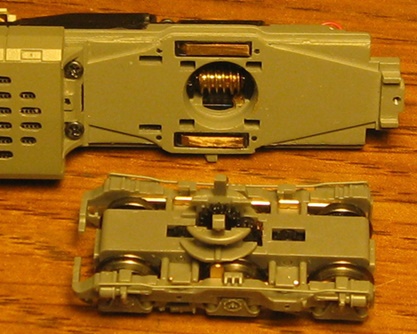

All twelve wheels provide pickup. The axle ends insert into holes (as opposed to dimples) in the axle wipers. Vertical extensions on top of the axle wipers contact flexible metal strips firmly mounted inside the chassis. Wires soldered to the tops of said metal strips transfer current to the decoder board. Plastic collars on top of the truck gear towers clip inside round openings in the chassis. The trucks pull off and go back on very smoothly and easily. As delivered, there appears to be little or no lubrication on the gears (not necessarily a bad thing since it doesn't seem to really need it).

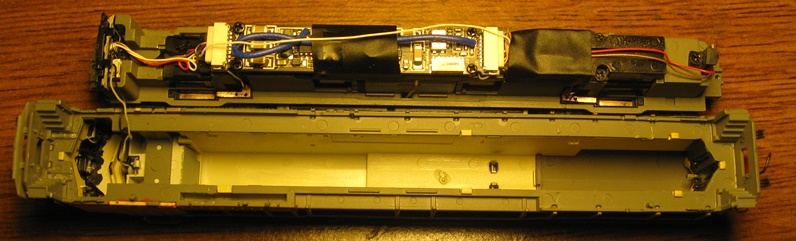

For sound-equipped models, the decoder board is screwed to a plastic bracket that mounts on top of the motor. The Stealth versions have an Next18 DCC interface on the DC motherboard. Wiring harnesses for track power, lighting control, motor control, and speaker control plug into sockets on either end of the board. A couple of pieces of black tape cover up some of the wiring (presumably to prevent it from moving around and causing trouble). A small LED board for the backup light is wired up on the rear of the chassis. A larger board (with five individual LEDs for the headlight, ditchlights and numberboards) is wired up on the front of the chassis. A small wiring harness plugged into the forward LED board runs up into the shell and provides current for the cab lighting. A small button on the decoder board allows you to reset the decoder to factory defaults (for situations where writing CV8 doesn't fix your locomotive's problems or you don't have the ability to write CV's at all). I'm assuming the large blue wire is the radio antenna for the Rolling Thunder system.

F0 controls the LEDS for the headlight, backup light and numberboards. F7 controls the ditchlight LEDs. Once turned on, standard behavior is for all seven LEDs to be lit when the locomotive is parked. Once you start the locomotive moving, the headlight and backup light become directional (IE, move forward and the backup light turns off). The cab interior light stays on until speed step 3, at which point it turns off (if you don't want a cab interior light at all, set CV208 to 0). An interesting feature of the ditchlights is that they will start strobing (alternately) when the horn is blown. All lighting is white and very bright. When the locomotive is put on the rails, all sounds are off. However, once you start it moving, sound comes on and stays on until you either mute it with F8 or pull the locomotive off the rails.

Based on reports from others (along with my own experiences), the first release of these models had a lot of problems (ranging from the annoying to the dire). In fact, one major online dealer received so many returns that they had to stop sending out replacement locomotives altogether. Evidently people who had received replacements wound up having to return those as well, which was adding up to a whole lot of expensive overhead for said dealer - to the point that they eventually had to resort to simply issuing refunds.

According to BLI, the problems were caused by "underrated" (and unauthorized) electronic components installed on 20% of the AC6000 decoder boards. Some of the AC6000's were reportedly delivered totally DOA (no lights, no sound, no motor, no nothing), whereas others would last a day or two before giving up the ghost. BLI states that the problems only occur when the locomotives are operated in analog mode (consequently, I didn't even try to test mine using DC power). However, I know of at least a few people who had their AC6000's die on DCC layouts. In any case, should you wind up with a bad decoder BLI will either send you a replacement (to install yourself) or issue you an RA# so that you can send the locomotive back to them (at their expense) for repairs. More information from BLI HERE.

All that said, I have certainly read plenty of reports from folks who didn't experience any problems at all with theirs. So, they're not all duds (not yet, anyway). As for my own experiences, I purchased two of these and although I did run into some initial wheel and truck-related annoyances, I haven't had any decoder problems yet (knock on wood).

The first one that I tested was extremely balky out of the box and I had to resort to some fairly Herculean wheel and track cleaning efforts in order to get it to run properly (a fairly common problem with these models, or so I've read). Once the wheels were clean I put it through its paces by running it around in circles for a couple of days, after which the second annoyance emerged - namely, more balkiness. After inspecting the wheels and track to make sure that everything was clean and spotless, I decided that the problem must be with the axle wipers. So, I tried applying a bit of E-Z Lube (conductive lubricant) to the holes in the wipers where the axle ends insert. And lo, this wound up solving all of its problems.

My second unit ran great right from the get go - no wheel cleaning required at all. However, after a couple of days worth of roundy-rounding I once again ran into problems with the axle wipers. And although the problem was different this time (a lot of annoying squeaking as opposed to balkiness), the solution remained the same - take the trucks apart and put some E-Z Lube on the axle ends. And yes, once suitably lubricated, all the squeaking sounds away. Additionally, the bendy metal contact strips in the chassis (similar in function to the ones used by Atlas, et al in their diesels) may require some tweaking in order to get optimum current conductivity. I wound up bending mine downwards a bit to get firmer contact with the axle wiper tips.

So, let's say you get one that isn't DOA, hasn't blown up, has nice clean wheels, has properly conduct-a-lubed axle ends and properly adjusted contact strips. Well, amazingly enough, you will find that you've got yourself a very respectable locomotive indeed. Mine runs smoothly and quietly for the most part, although it does emit a noticeable electronic whine when the sound is turned off. Pickup is solid (no stalls, stuttering or problems with the sound cutting in and out), although one does have to remain extremely vigilant about keeping the wheels and track spotlessly clean. Throttle response is nimble, slow speed creep is "one tie at a time", and the top end speed is quite reasonable. Pulling power is decent (if unspectacular), with mine able to haul around thirty assorted 50' freight cars through curves on level track (or about seven fewer cars than my Kato SD70ACe can handle). No problems with any of the wheels derailing (even on curves as sharp as 9.75" radius). The sound is robust and nicely rendered (even without bringing a Rolling Thunder system into the equation).

Due to all of the above caveats, I can't really rate these models any higher than a "C". Yes, the potential is there to find a decent one - I just don't know what your odds are of doing so. About all I can say is "try before you buy" (if at all possible). And failing that, make sure that you have the option of returning it should things not work out.

Prototype -

Meet the winner of the horsepower race: the GE AC6000CW with 6000 hp under the hood - thats more than the Big Boys were able to do. They are about 76' long from coupler face to coupler face and are often run in pairs. On today's railroads, they are the king of the hill! BLI is producing these monsters from GEs Erie, PA plant and our models do them justice. Our new Paragon3 N Scale AC6000s more than do their life-sized prototypes justice.

Model Features -

- ABS Body with Heavy Die Cast chassis for max. tractive effort

- Features the ALL-NEW N Scale Paragon3 with Rolling ThunderTM SOUND & Control System (Rolling ThunderTM transmitter onboard)

- Integral DCC Decoder with Back EMF for Industry Best Slow Speed Operation in DC and DCC

- Precision Drive Mechanism engineered for continuous heavy load towing and smooth slow speed operation

- Powerful Motor

- Premium Caliber Painting with Authentic Paint Schemes

- Prototypical Light Operation with Golden White LED Headlight, Rear Light

- Couplers: (2) MicroTrains #1015

- Many Separately Applied Details

- Minimum radius: 9.75 radius or greater recommended.

DCC/Sound Features -

- Operates in DC & DCC (use DCMaster for DC sound)

- 2 Selectable Bells

- 3 playable horns

- 1 long, non-looped horn

- 1 alternate horn for locomotives with a second horn

- 4 Times Expanded Autopilot storage

- Expanded Startup and Shutdown sequences

- 2 Watt Audio output

- 84 db signal to noise ratio

- 16 bit audio resolution

- 24 sounds with separate volume control

- Unmatched frequency response as low as 20 Hz when paired with Rolling ThunderTM subwoofer kit

- 8 simultaneously playable audio channels

- Functional Dynamic Brake with Grid Blower sounds

- Improved motor control in DC and DCC

- Motor short circuit protection

- Works with NMRA standard DCC controllers

- Automatic Dual Mode: Works with DC power packs or DCC

Shell Removal -

The shell is held to the chassis primarily by its coupler screws, so your first job is to unscrew those and get the couplers out of the way. Next, four plastic "claws" molded inside the shell clip inside of slots in the chassis. So, once the couplers are removed, it's just a matter of using small screwdrivers to spread the sides of the shell apart (thus freeing up the claws) and then gradually working the shell up and off. Note that wires run from the forward lightboard on the chassis to an LED board inside the cab, so you won't be able to completely separate the shell from the chassis until you disconnect that.

Grade: C (due to the bad decoder QC - although potentially an "A" if you get a good one and can address any truck pickup/noise issues)