Introduced: 2008 (MRC sound decoder version), 2013 (Soundtraxx sound decoder version) and 2017 (DCC-Ready version)

Like their 2007 Challenger model, Athearn's Big Boy is, in a word, perfect. Honestly, I can't find anything bad to say about it. The paint and detailing are breathtaking, the factory-installed DCC-Sound feature is tons of fun, it pulls like a freakin' elephant, and overall performance is simply flawless in every way.

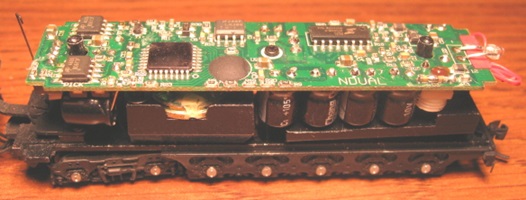

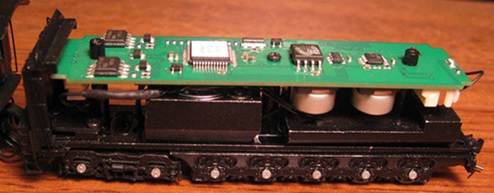

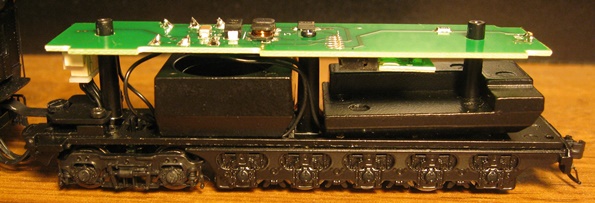

The chassis is all-metal and quite hefty. Up until 2017, the motor was an open-sided / skew-wound three-poler (which was a bit of false advertising on Athearn's part since they described it as having five poles in the manual). Starting with the 2017 production run, the motors were changed to actual five-polers. The motor driveshafts are each equipped with a flywheel. Six of the eight drivers on each engine provide pickup. The forward drivers on the front engine are equipped with traction tires, as are the rear drivers on the back engine. All 14 tender wheels provide pickup. The pilot and trailing trucks are electrically neutral. Wires are used to conduct current from the base of the engines to a PC board mounted atop the chassis. Still more wires ferry current from the PC board in the engine back to the decoder board mounted inside the tender. The tender drawbar is screwed to both the tender and the locomotive. The wiring between the two is basically free-floating (and there's a lot of it). Fortunately, it doesn't seem to cause any problems (vis'a'vis derailing).

One driver pair per engine is geared (the ones with the traction tires). All gearing is plastic. A directional headlight is mounted to the pilot assembly (with long wires running back to the PC board on top of the chassis). Said light also provides illumination for the attached numberboards. A back-up light is mounted to the decoder board in the tender. A Micro-Trains coupler is mounted to the tender chassis. As delivered, there is no coupler on the pilot. However, 2008 Big Boys include an ala-carte MT coupler for the pilot should you wish to install it there (said ala carte pilot coupler was not included with the 2013 Big Boys, although the owner's manual was not changed to reflect this ommission). Both engines are articulated (pivot), consequently this model can run on curves as sharp is 11"-radius. All wheels are blackened and low-profile (no problems on Code-55 rails).

One note - this is a big locomotive (obviously). And although it can actually handle 11"-radius curves without difficulty, the same cannot be said for 9.75" curves. When faced with the full 9.75" torture test (180 degrees), the cab-end of the locomotive will actually swung out enough to pull the forward tender truck off the rails. No, not a complaint (I mean, the fact that it actually runs on 11" curves is pretty amazing). Rather, just a note of caution aimed at the hopelessly optimistic "small layout" guys out there.

| MRC Decoder | Tsunami Decoder | |

|  |

As noted above, these models originally came with MRC sound decoders. However, starting with the 2013 production run the decoders were changed to Soundtraxx Tsunami's. Operating the original MRC decoders on DC layouts required a special handheld remote (included with the locomotive). Conversely, the Soundtraxx decoders can be operated directly with a normal DC power supply. Thanks to the large/enclosed speaker, the sound on either version is quite impressive.

Some DCC systems have problems programming the original MRC decoders (and, for that matter, sound decoders in general). My Lenz system is unable to read the feedback responses from the decoder when programming it on the programming track (something to do with the low current generated by the decoder when talking back to your system). So, when making changes you just kind of have to trust the digital gods that your changes are actually getting made, because your system is going to tell you that there isn't a locomotive on the programming track at all. Ultimately, I didn't have any problems making CV changes on mine, but it did take longer than normal (what with all the misleading error messages). As for programming "on the main", I couldn't get that to work at all... But again, this is a problem between certain DCC systems and certain sounds decoders and isn't a specific problem with this locomotive (per se). The good news is that my system has no problems programming the newer Tsunami decoder.

Notes & Miscellania -

#1 - The first DCC-Ready version (IE no sound decoder) was released as part of the 2017 production run. As pictured below, the tender PC board on this version comes with a European-style 6-pin DCC interface (NEM651). It also includes the same speaker enclosure that comes with the sound-equipped models. I'm told that the DCC socket was changed to 18-pin NEM662/Next18 starting with the 2021 release (although I haven't actually taken mine apart in order to verify that).

Removing the tender shell in order to access the DCC plug is a somewhat complex procedure. You first have to remove the two screws on top of the shell (hidden underneath a couple of press-fit detail parts). Next, you have to remove the forward and rear end-wall pieces (the forward one clips in place and the rear one is held on with two screws). Lastly, you have to unscrew the coupler screw. At this point you should be able to slide the shell back and off. I'd recommend using the supplied parts diagram in the owner's manual to help guide you through the process.

#2 - Although these are (for the most part) sensational locomotives, they are also extremely complex models that are quite difficult for the average modeler to work on. Case in point - I ran into a rather vexing problem with one of mine (one from the 2017 production run) that I was never able to fix. Here's the deal - as I normally do when I get a new locomotive, I spent several hours running it around in circles in order to break in the mechanism (first in forward, then in reverse). Well, everything was hunky dorey after the forward part of the process. However, within seconds of switching it into reverse, the crank pins on both sides of the rear engine popped out of their driver holes. And as annoying as that might be, the fact that it's virtually impossible to get said pins plugged back into the drivers definitely added insult to injury. As near as I can tell, the pins are squared off on the ends and the holes in the drivers are also square. But for whatever reason, I was never able to get them seated properly back in their holes (IE, they would just pop right out the minute I put the locomotive back on the track and gave it some throttle). So, ultimately I had to just send it back to the manufacturer (twice) for repairs - something I rarely have to resort to. Unfortunately, Athearn never was able to adequately repair it for me and I finally just gave up on it. Fortunately for me, the example I purchased from the 2021 production run ran great right out of the box and exhibited none of the problems I had with the 2017 model. I dunno if something was changed or if they just tightened up the tolerances (and no, I'm not going to try to disassemble mine in order to find out). But in any case, 2017 appears to have simply been a bump in the road.

#3 - Smoke deflectors (aka elephant ears) were available starting with the second run (also 2008) -

#4 - Athearn eventually decided that their original tender drawbar design was too complex (making it extremely difficult for their service department folks to disconnect and reconnect the tenders when working on these models). Consequently, the drawbar was redesigned with the 2013 release -

The original version had sprung "V" mounts on both ends, whereas the new version has a simple loop on the locomotive end. Unfortunately, at least some of the 2013 Big Boys were delivered from the factory without the required spring on the "V" end. Said spring connects to the notch in the drawbar and loops around the post behind the drawbar -

Without the spring to center the drawbar, the tender tends to ride down the rails a bit crookedly. The good news is that the Athearn parts department is (as of this 2013 writing) supplying replacement springs to those who ask for them. However, the installation of said spring is a rather complicated procedure, so if you're not comfortable with the idea of tearing your tender apart you might want to just send yours in to Athearn for repairs.

Here's what Athearn has to say about their Big Boy -

This stunning reproduction of the 4-8-8-4 Big Boy is the result of a focused determination to accomplish one thing: create the finest operating miniature representation of the prototype available. Giving life to all the details are authentic sounds that are channeled through a factory installed DCC and soundboard with speakers. The DCC decoder automatically senses what type of power supply is in use (conventional DC or NMRA compliant DCC) and adapts its functions. The modeler doesn't have to do a thing.

Functions and sounds available to DCC users include:

- Bell

- Whistle

- Water injector

- Air release

- Blower hiss

- Fire box door

- Lighting direction

- Coupling

- Brake squeal

- Conductor's voice

- Sand release

- Cylinder cock/flange squeal

A handheld wireless controller is included (MRC version) for use with conventional DC power supplies. With it, modelers can control six sound functions as well as speed and direction. The N Scale 4-8-8-4 Big Boy includes a history book and instruction book for quick reference.

Features include:

- New tooling

- Fully assembled

- Razor-sharp printing and painting

- Dual Function Decoder with SOUND and handheld remote control

- Prototype specific details

- Boiler backhead with full details.

- Individually applied detail parts such as piping, valves, generators, etc.

- Eccentric cranks operating on both sides in correct direction.

- Front and rear engines (cylinders and coupled drive wheel sets), both pivot for 11" recommended min. radius.

- Pilot has open/closed positions. Coupler pocket can be inserted to mount coupler after removal of dummy coupler.

- Undecorated versions include all parts for that prototype.

- Factory installed DCC sound board with speaker, mounted in the tender.

- DCC decoder automatically senses the power supply type (either DC or NMRA compliant DCC system).

- Hand held remote control unit for DC operation (MRC version).

Grade: A (although an "F" for the 2017 production run as far as I'm concerned)

Reviewed: 06/08 Model Railroader ("One of the largest locomotives ever built is available as a sound-equipped N scale model. The accurately detailed Athearn Big Boy 4-8-8-4 also has power worthy of its prototype. The N scale locomotive's drawbar pull is almost double that of the average N scale steamer. Equipped with a Model Rectifier Corp. (MRC) dual-mode Digital Command Control (DCC) sound decoder, the Athearn N scale Big Boy brings user-controlled sound effects to both DCC and DC layouts.

All dimensions of the Athearn N scale Big Boy match drawings in the Model Railroader Cyclopedia vol. 1: Steam Locomotives (Kalmbach Publishing Co.) Our sample came decorated as no. 4009. The aluminum-colored lettering is crisp and straight. The journal covers on the model's trailing truck are painted silver. The UP began this practice in the 1950s to indicate roller bearings. However, to be consistent with this era, the tender's journal covers should also be painted silver instead of black. The overall detail level on this N scale Big Boy is not that far removed from the Athearn HO scale Big Boy. The N scale model's molded-in detail is sharply defined. The boiler handrails and almost all piping are separately applied. Correct for the first 20 Big Boys as-built, our sample has aftercooler piping under the pilot handrails. The pilot has a swing-out coupler pocket. The user-installed operating front knuckle coupler mounts at the correct height per National Model Railroad Association standard S-2.

The Athearn N scale Big Boy is made primarily of plastic and uses some of the same parts as the Athearn N scale Challenger. These parts include the enclosed all-weather cab and the 14-wheel centipede tender. Unfortunately, like the Challenger, the Athearn Big Boy has a black Phillips head screw inside the front smokestack. It would have been less noticeable if the screwhead was painted graphite to match the smokestack. Drivetrain and electronics. A can motor with two metal flywheels inside the boiler drives both the front and rear engines through separate worm gears and gearboxes. The rear drivers of the rear engine and the front drivers of the front engine come with rubber traction tires and contribute to the Big Boy's impressive 2.9 ounce drawbar pull, equivalent to 73 N scale freight cars on straight and level track. On the prototype locomotive, only the front engine is articulated. On the Athearn Big Boy, the rear engine also swivels. This, along with .05" of lateral motion in the wheelsets of the centipede tender's pedestal truck, allow the model to negotiate tight-radius curves.

I ran the model around an 11"- radius oval of Kato Unitrack and through an Atlas code 55 161/4"-radius curve and no. 6 turnout without interruption of sound. The Big Boy looks better rounding 20" radius or greater curves. Most of the model's electronics are inside the tender. A drawbar and wires permanently connect the engine and tender. Although exploded-view diagrams are included, disassembly of the model isn't recommended.

In DC the sounds and lights started at 3 volts. At 8 volts the model crawled at 2.8 scale mph. The Big Boy reached a top speed of 67 scale mph at 12 volts. I measured the locomotive's speed in DC using an MRC Tech 4 power pack. Using the included six-button remote controller provides smoother speed control in DC. First I set the power pack to 12 volts, then I adjusted the model's speed and direction with the controller. In DCC the Athearn Big Boy performed best when I used a 12-volt power supply. Under 128 speed steps the model moved steadily at 3 scale mph and accelerated smoothly to a top speed of 68 scale mph.

The MRC sound system in the Big Boy is comparable to the one in Athearn's N scale Challenger. The overall sound quality is good. The speaker in the tender is well-enclosed, so there aren't any buzzes or rattles. The engine produces four chuffs per wheel revolution, synchronized to each engine. The default whistle is the correct steamboat type, but I found this feature to be the weakest of all the sound effects. The whistle has an artificial-sounding echo effect. With the six-button remote controller I triggered the bell and whistle and programmed some sound effects in DC, including changing the whistle type. When using DCC, the sound system supports 28 functions. Most of the electronic features are programmable. The instruction manual includes a configuration variable (CV) table.

User-controllable sound and powerful pulling capabilities make this new N scale locomotive fun to operate. If you're an N scaler who has a layout with broad curves and you're a fan of big UP steam, you should make room in your roundhouse for the new Athearn Big Boy. $424.98")